- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 226 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

A medical cleanroom is a special room. The air, temperature, and humidity are controlled. These rooms are important in the medical field. They help keep patients, products, and research safe. Cleanrooms have ISO ratings. The rating shows how clean the air is. It counts tiny particles in the air. There are different types of medical cleanrooms. Some are for research, devices, or medicine. Each type has its own rules. Amber builds these cleanrooms for people all over the world.

Type of Cleanroom | Description | Cleanliness Standards |

|---|---|---|

Medical Research Cleanrooms | Used for careful research. They need very clean air. | ISO Class 5-7 |

Medical Device Cleanrooms | Used to make and test medical devices safely. | ISO Class 5-8 |

Pharmaceutical Cleanrooms | Keeps medicine pure when making products. | GMP Grades A-D (A = ISO 5) |

Medical cleanrooms control air, temperature, and humidity. This helps keep patients and products safe.

There are different cleanrooms for research, medical devices, and pharmaceuticals. Each type has its own cleanliness rules.

ISO and EU GMP standards sort cleanrooms by air cleanliness. These standards help you pick the right cleanroom for your needs.

Air quality is very important in cleanrooms. HEPA and ULPA filters remove tiny particles and germs.

Following cleanliness rules is needed to stop contamination. This keeps medical places safe.

Amber makes cleanrooms that meet strict standards. These cleanrooms can change to fit your needs.

Cleanrooms use regular checks and strong filters to stay safe.

Picking the right cleanroom protects staff, patients, and research. This helps make sure you get good results.

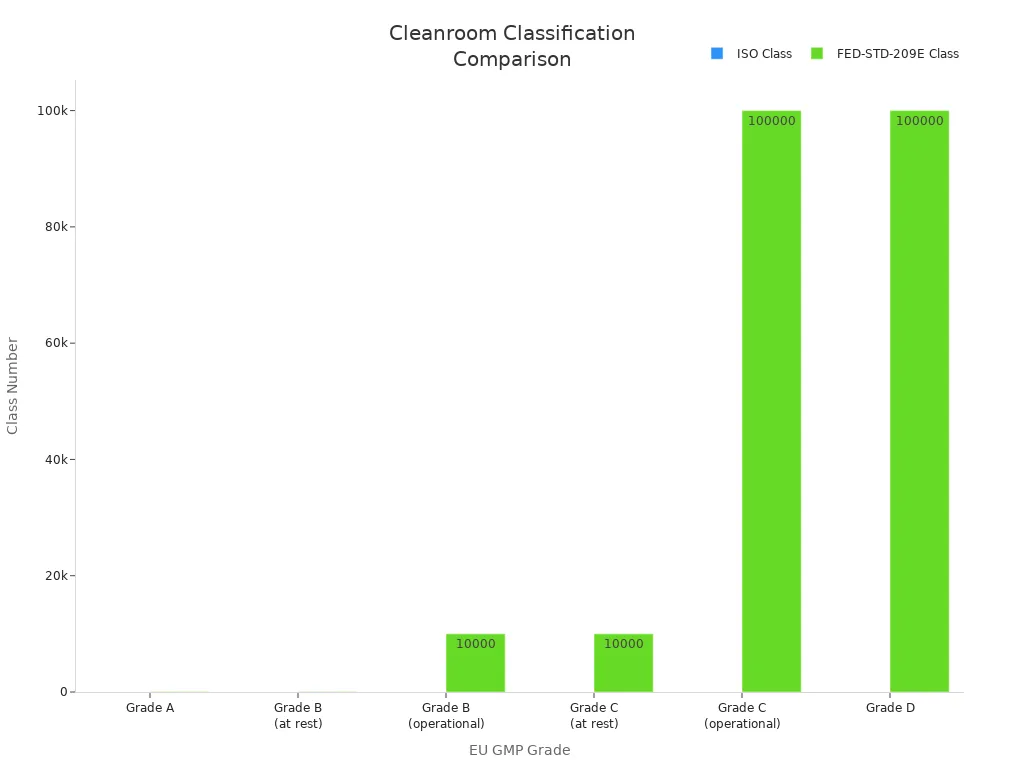

There are two main ways to sort medical cleanrooms. These are called ISO and EU GMP. They show how clean the air is inside. ISO 14644-1 is used in many countries. EU GMP is mostly used in Europe for medicine and devices.

Here is a table that compares these standards:

EU GMP Grade | ISO Class | FED-STD-209E Class | Description |

|---|---|---|---|

Grade A | ISO Class 5 | Class 100 | Highest cleanliness for critical operations |

Grade B (at rest) | ISO Class 5 | Class 100 | Supports Grade A environments |

Grade B (operational) | ISO Class 7 | Class 10,000 | Maintains cleanliness during production |

Grade C (at rest) | ISO Class 7 | Class 10,000 | Prepares for critical operations |

Grade C (operational) | ISO Class 8 | Class 100,000 | Accommodates higher particle counts |

Grade D | ISO Class 8 | Class 100,000 | General cleanroom environment |

Note: ISO uses numbers from 1 to 9. Lower numbers mean cleaner air. EU GMP uses Grades A to D. Grade A is the cleanest.

You can look at this chart to see the comparison:

Amber makes medical cleanrooms that follow both ISO and EU GMP rules. This means you get the right cleanroom for your needs anywhere.

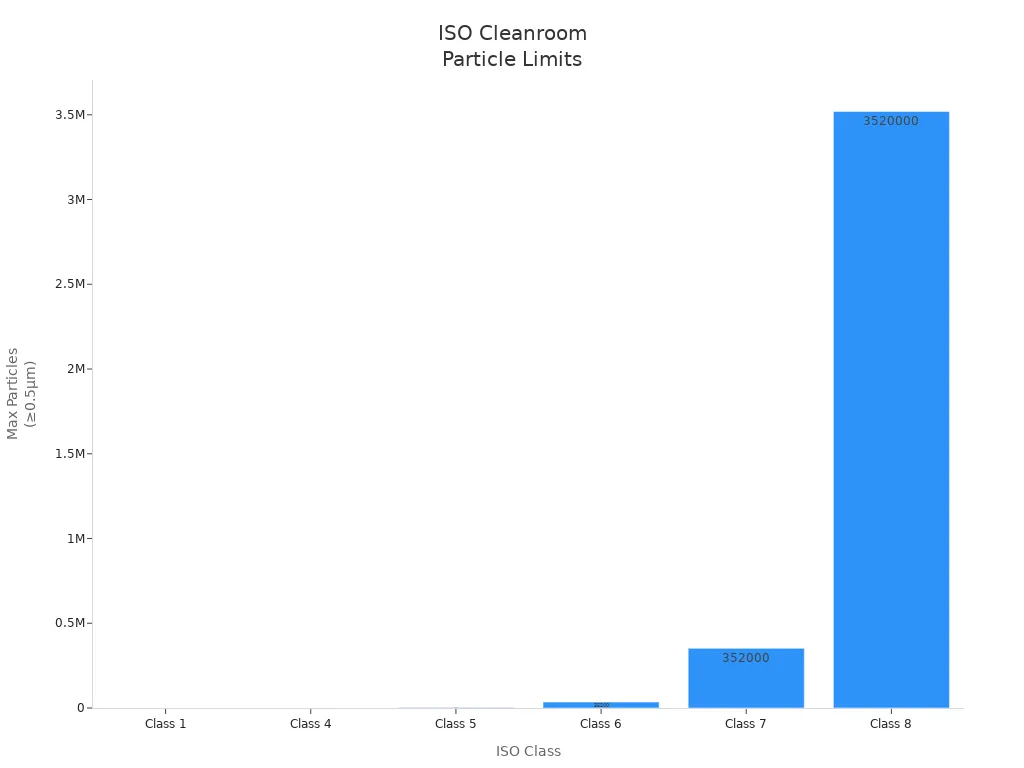

Air quality matters a lot in medical cleanrooms. Each ISO class sets a limit for tiny particles in the air. For example:

ISO Class 5 lets up to 3,520 particles (0.5 micrometers or bigger) in one cubic meter.

ISO Class 7 lets up to 352,000 particles (0.5 micrometers or bigger).

ISO Class 8 lets up to 29,300 particles (5 micrometers or bigger).

Even ISO Class 8 is much cleaner than a normal room. You need this control to keep products and patients safe.

Amber uses special air filters and monitors. These help keep the air clean and meet tough rules every day.

It is hard to keep a cleanroom up to standard. Some big problems are:

Controlling particles and germs.

Handling lots of data from air monitors.

Training people to not bring in dirt or germs.

Saving energy and money.

Stopping cross-contamination when making more than one product.

Amber helps you fix these problems. The company uses smart designs, good training, and automatic systems to keep your cleanroom safe.

Tip: Always check if your cleanroom meets the newest ISO or EU GMP rules. This helps you avoid trouble and keeps your work safe.

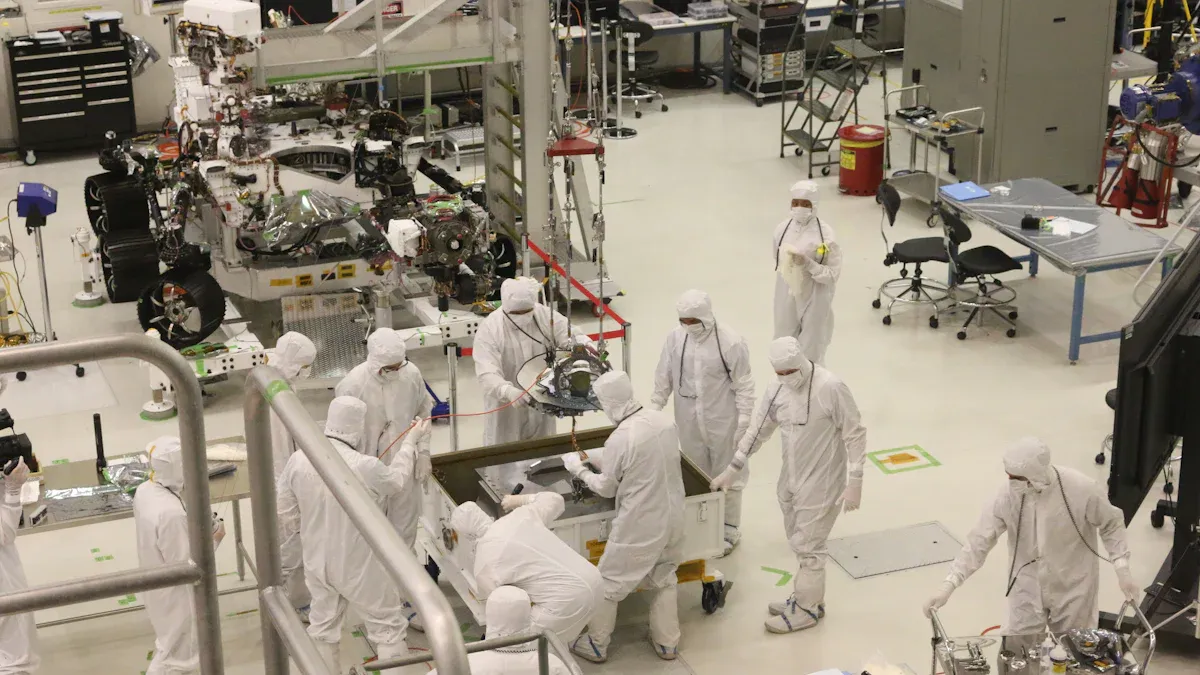

Image Source: unsplash

There are different medical cleanrooms. Each one does a special job. You need to pick the right cleanroom for your work. This keeps your products, research, and patients safe. Let’s look at the main cleanrooms used in medicine.

Medical device cleanrooms help you make and test devices. These include pacemakers, surgical tools, and diagnostic equipment. The rooms keep dust and germs away from your products. You must follow strict air cleanliness rules. The ISO class depends on the device you make.

Here is a table that shows ISO classes for medical devices:

ISO Class | Application Description |

|---|---|

Class 3-5 | Used for implantable and sterile Class III devices (e.g., pacemakers, orthopedic implants) |

Class 6-7 | Suitable for Class II devices, including surgical tools and diagnostic equipment |

Class 8 | Common for assembly and packaging of non-sterile medical devices |

Amber gives you cleanrooms that meet these ISO classes. You get strong HEPA and ULPA filters. Real-time air checks help you stay safe. Amber’s design lets you change or grow your cleanroom. You can trust Amber to help you follow all the rules.

Pharmaceutical cleanrooms keep medicine pure and safe. You must control dust, germs, and chemicals. These rooms need the cleanest air for making sterile drugs. You must watch the air for particles all the time.

Here is a table that shows ISO classes and uses in pharmaceutical cleanrooms:

ISO Class | Maximum Particles (≥0.5 micrometers) | Typical Use in Pharmaceuticals |

|---|---|---|

Class 1 | 10 | Rarely used |

Class 4 | 352 | Rarely used |

Class 5 | 3,520 | Aseptic processing |

Class 6 | 35,200 | Intermediate cleanliness |

Class 7 | 352,000 | Secondary packaging |

Class 8 | 3,520,000 | Component assembly |

Amber builds pharmaceutical cleanrooms for you. You get many filters, pressure control, and automatic systems. These stop cross-contamination. Amber’s team helps you follow all the rules. You can focus on making safe medicine while Amber controls the environment.

Medical research cleanrooms help you work in labs. You might study cells, genes, or new treatments. These rooms need flexible air control. You may change air flow or filtration for each project. The design has biosafe walls and furniture for safety and comfort.

Here is a table that compares cleanroom types:

Cleanroom Type | ISO Class Range | Air Filtration Requirements | Design Features |

|---|---|---|---|

Medical Research | 5-7 | Powerful filtration system | HardWall, biosafe, ergonomic furniture |

Pharmaceutical | 5-7 | 240-600 air changes/hour | HardWall, strict environmental control |

Medical Device | 5-8 | Compliance with aseptic standards | Aseptic environment, terminal sterilization requirements |

Amber gives you bio-lab cleanrooms for your research. You get modular HEPA filters and airflow you can adjust. Amber’s cleanrooms help you keep your lab safe and clean. You can trust Amber to support your cleanroom needs.

Tip: Always match your cleanroom type to your work. The right cleanroom protects your products, research, and team.

Operating room cleanrooms are very important in hospitals. These rooms help keep surgeries safe. They lower the chance of infection. The air must be super clean. Modern HVAC systems use three filters. The last filter is a terminal filter with H13 or H14 quality. This setup removes almost all particles from the air. When no one is inside, the room should have almost no particles bigger than 0.5 micrometers.

You need to follow special rules. ASHRAE Standard 170-2008 and ANSI/ASHRAE Standard 170-2017 set rules for airflow, temperature, humidity, and filtration in operating rooms.

Standard | Description |

|---|---|

ASHRAE Standard 170-2008 | Controls airflow, temperature, and humidity in operating rooms. |

ANSI/ASHRAE Standard 170-2017 | Gives rules for air filtration in patient care areas. |

Amber makes operating room cleanrooms that follow these rules. You get advanced laminar flow systems. The air changes quickly in these rooms. Amber uses barriers to keep sterile and non-sterile areas apart. These cleanrooms help lower infections after surgery. They keep patients safe. Amber can change the room to fit your hospital. You will meet all cleanroom requirements for hospitals.

Dental and veterinary cleanrooms keep people and animals safe during procedures. These places have special risks. Dental waterlines can have lots of germs. This can make animals and staff sick. Biofilm sludge can block tools and spread bacteria. Common germs are Legionella, Pseudomonas aeruginosa, and non-tuberculous Mycobacterium. Fast tools make aerosols that carry germs in the air.

To keep things safe, you need strong cleaning and care. You should shock waterlines to clean them. Test water every few months. Removing biofilms needs regular cleaning and good habits.

Amber gives custom cleanrooms for dental and vet clinics. You get modular filters and surfaces that fight germs. Amber’s designs make cleaning easy. They help control air quality. Amber helps you manage bioaerosols and protect your tools. With Amber, you can follow rules for safe water and air in your clinic.

Biotechnology cleanrooms help with work using sensitive biological materials. You must control particles, biological agents, and cross-contamination. These rooms need ISO Class 5 or better. You need lots of air changes to keep air clean. Hard walls make cleaning easy. They stop particles from hiding in cracks. You must also control temperature, humidity, and pressure to protect samples.

Laminar airflow and multi-stage HEPA filters are very important. These features help you follow ISO 14698 for biocontamination control. Biotechnology cleanrooms keep your research safe and trustworthy.

Amber builds modular biotech cleanrooms with these features. You get pressure zones you can change and strong filters. Amber uses hard walls and advanced airflow. These cleanrooms help you follow strict ISO rules. They keep your work safe. Amber’s modular design lets you grow or change your space when you need to.

Tip: Picking the right medical cleanroom protects your staff, patients, and research. Amber can help you choose the best cleanroom for your clinic, lab, or hospital.

Image Source: unsplash

Cleanrooms need strong air filters to stay safe. HEPA filters catch almost all tiny particles. They remove 99.97% of things as small as 0.3 microns. This is very important in medical cleanrooms. ULPA filters can trap even smaller things. Countries use rules like IEST-RP-CC001, ISO29463, and EN1822 for these filters. You must test filters with ISO 14644-3 methods. In healthcare, HEPA filters help stop germs and keep people safe.

Studies show HEPA filters lower germs in the air. This helps stop infections and follow health rules.

Cleanrooms often need more than one filter. The first filter catches big dust. Next, HEPA or ULPA filters catch tiny particles and germs. This keeps air clean for work in pharmaceutical and medical device cleanrooms.

You must check air quality all the time. Special monitors watch for particles and warn you if they go up. This helps you fix problems fast. You can keep medical research cleanrooms safe and follow strict rules.

Amber gives you strong filtration systems. You get HEPA and ULPA filters, many filter stages, and real-time air checks. These help you meet all air quality rules in medical cleanrooms.

You can change modular cleanrooms to fit your work. If your job changes, you can move walls or doors. This helps you keep up with new rules and tasks.

You can add or take away modules as your business grows. This makes it easy to make your cleanroom bigger or smaller.

Modular cleanrooms go up fast. You save time and money. Building off-site makes less waste and speeds things up.

Amber gives you custom engineering for your cleanroom. You get designs that fit your needs. Amber helps you follow rules and get ready for changes.

Tip: Modular cleanrooms help you change fast. You can keep working and meet new standards.

You want your cleanroom to last a long time. SUS304 stainless steel is strong and safe. It does not have heavy metals and is safe for people.

SUS304 does not rust and stands up to chemicals. You can use strong cleaners and not hurt it. This keeps your cleanroom safe and clean.

Smooth stainless steel stops germs from hiding. You can clean and sterilize it easily. This helps control contamination.

Amber uses special ways to build cleanrooms. You get smooth panels and strong joints. These make cleaning easy and keep your cleanroom in good shape.

Advantage | Description |

|---|---|

Biosafety | Non-toxic, safe for contact with people. |

Easy to Clean | Smooth surface limits bacteria and allows for easy sterilization. |

Corrosion Resistance | Durable, resists chemicals and does not oxidize. |

Note: Using the right materials and design helps you meet all cleanroom rules. This keeps your space safe for many years.

You must control air pressure in your cleanroom. Positive pressure stops outside air from coming in. This protects products in places like pharmaceutical manufacturing. Negative pressure pulls air inside the room. It keeps dangerous particles from getting out. You use negative pressure for rooms with harmful germs or chemicals. Setting the right pressure keeps clean and dirty areas apart. Amber’s cleanrooms let you change pressure zones as needed. This helps you follow cleanroom rules and keeps your work safe.

Airflow zoning splits your cleanroom into different areas. Each area has its own airflow pattern. Unidirectional airflow pushes particles away from important workspaces. This stops cross-contamination between areas. For example, you can have a sterile zone for surgery. You can also have a less strict zone for storage. Amber designs cleanrooms with clear airflow paths and barriers. This makes it easy to keep each area as clean as needed. You lower the risk of spreading germs or dust between zones.

Tip: Wipe surfaces using overlapping strokes. Start with spots that are hard to clean. This helps you remove more dust and germs.

You need to watch your cleanroom all the time. Monitoring systems check air quality, temperature, humidity, and particle counts. Alarms warn you if something goes wrong. You can fix problems before they hurt your products or research. Amber’s cleanrooms have real-time monitoring and smart alarms. You see data on a screen and get alerts if levels change. This helps you keep your cleanroom safe and within standards.

Amber gives you automated barriers to control contamination. These include air showers, pass boxes, and interlocking doors. Air showers blow off dust and particles before you enter. Pass boxes move items in and out without opening the main door. Interlocking doors make sure only one door opens at a time. These features lower the chance of outside air or particles getting inside. You also get easy-to-clean surfaces and strong filters. Amber’s solutions help you follow strict rules and keep your cleanroom safe.

Key contamination control features in Amber cleanrooms:

High-efficiency filtration systems

Regular cleaning with the right agents

Employee training on hygiene and gowning

You need all these features to stop cross-contamination. Cleaning and disinfecting are very important. Use HEPA-filtered vacuums and lint-free wipes. Pick cleaning agents that do not leave harmful residues. Disinfect with safe chemicals like hydrogen peroxide. These steps help you keep your cleanroom safe for people and products.

Cleanrooms are used in hospitals and clinics. These rooms help keep patients safe. They also support important medical work. Here are some ways cleanrooms are used:

Compounding pharmacies make sterile medicine. Cleanrooms stop contamination and protect patients.

Operating rooms use cleanrooms for clean air. This lowers infection risk during surgery.

Medical device factories use cleanrooms. You make implants and tools in a controlled space.

Research labs use cleanrooms for experiments. You get better results by controlling the environment.

Cleanrooms help hospitals meet safety rules. They protect patients, staff, and products from germs and dust. Amber builds cleanrooms for hospitals worldwide. You can trust Amber to design safe spaces that follow all rules.

Tip: The right medical cleanroom in your hospital lowers risks and helps care.

Pharmaceutical cleanrooms help make safe medicine. These rooms control particles and keep out germs. You use strong filters and follow strict cleaning steps. This stops contamination and keeps patients safe.

Medical cleanrooms help with quality checks. They keep the space clean so medicine stays pure. You follow air quality rules and cleanliness standards. This means your medicine is safe for people.

Amber builds cleanrooms for making medicine. You get strong filters, pressure controls, and smart monitors. You can focus on making good medicine while Amber handles the cleanroom.

Cleanrooms are used in research and biotech labs. These rooms help control contamination and keep experiments accurate. Here are some benefits:

You lower contamination risk.

You make experiments easier to repeat.

You get better accuracy and precision.

You control temperature and humidity.

You use the space for different research jobs.

Cleanrooms keep biological materials safe. They help you make good products and set the best conditions for work. Amber gives labs cleanrooms that fit their needs. You get modular designs and strong filters for your research.

Note: Cleanrooms help you get good results and keep labs safe. You can trust Amber for any research or biotech project.

If you want a company that builds real cleanrooms, Amber is a good choice. Amber has finished over 1,000 turnkey cleanroom projects in more than 120 countries. This means you can count on Amber to help you, no matter where you live or what you need.

Amber’s cleanrooms are used in hospitals, labs, and factories around the world. Here are some things Amber has done:

Hospital Operating Rooms: Amber made cleanrooms for hospitals in Asia, Europe, and Africa. These rooms help doctors do safe surgeries. Patients get better faster because the air is clean and has no germs.

Pharmaceutical Plants: Amber built cleanrooms for medicine makers in the Middle East and South America. These rooms keep drugs safe and pure. Amber’s work is used in places that make vaccines and fill medicine bottles.

Biotech and Research Labs: Amber made modular cleanrooms for research centers in North America and Australia. Scientists use these rooms to study cells and find new treatments. The cleanrooms help them get good results.

Dental and Veterinary Clinics: Amber made custom cleanrooms for dental and animal care centers. These rooms keep both patients and staff safe from germs.

Amber’s team has more than 20 professional engineers. They help you from the first design to the final setup. You get help at every step.

You can see why Amber’s global work is helpful:

Benefit | What It Means for You |

|---|---|

Proven Track Record | You get a partner who knows how to fix problems. |

Local Compliance | Your cleanroom follows local and world rules. |

Fast Delivery | You save time with Amber’s modular systems. |

Custom Solutions | You get a cleanroom that fits your needs. |

Ongoing Support | You can call Amber for help after your room is built. |

Amber uses the same high standards everywhere. You get cleanrooms with strong HEPA filters, stainless steel walls, and smart monitors. Amber’s projects show you can have a safe, clean space anywhere in the world.

If you want to see more, you can go to Amber’s website for photos and stories: Amber Cleanroom Projects.

Tip: When you pick Amber, you join a group of hospitals, labs, and factories that trust Amber for clean, safe spaces.

First, think about what your job needs. Every job in healthcare, research, or making things is different. You need to know how big your space is. Think about how you will use the cleanroom. Will you need more space later? You should also look for dangers like germs or chemicals. These can hurt people or products. The right cleanroom helps you stop these risks and keeps your work safe.

Here is a table to help you see what matters most when picking a cleanroom:

Factor | Description |

|---|---|

Assessing Cleanroom Requirements | The kind of research changes what cleanroom you need, like pharmaceutical or microbiological testing. |

Facility Considerations | The size, shape, and plans to grow are important for cleanroom design. |

Risk Assessment | Finding dangers helps you pick the right cleanroom tools. |

Compliance with Regulatory Standards | Following rules keeps your work safe and honest. |

You should pick a cleanroom that fits your job. A hospital, lab, and factory all need different cleanrooms. If you want to grow, choose a cleanroom that can get bigger with you.

Amber helps you find and build the best cleanroom for your job. You get help from people who know the rules and how to design cleanrooms. Amber listens to what you want and helps you choose the right size and features. You can pick modular cleanrooms that change as your work changes. Amber gives you strong filters, easy-to-clean walls, and smart monitors. You get a cleanroom that fits your money plan and meets safety rules.

Tip: Ask Amber’s team about special choices. You can get a cleanroom that fits your work and future plans.

Amber’s turnkey service means you get help from start to finish. You do not need to worry about design or building. Amber does everything, so you can focus on your job.

You must follow rules to keep your cleanroom safe and legal. Different places have their own rules. You need to know which ones matter for your work. Some common rules are ISO 14644 for cleanrooms, EU GMP Annex 1 for medicine, and USP <797> and <800> for drug handling. If you make medical devices, ISO 13485 is important. These rules help you keep your cleanroom clean and protect people.

Here is a table that shows key standards:

Region/Standard | Key Requirements |

|---|---|

ISO 14644 | World rule for cleanroom class and air control. |

EU GMP Annex 1 | For making sterile medicine, covers germs and clothing rules. |

USP <797> and <800> | Rules for making and handling drugs, uses ISO classes. |

ISO 13485 | Quality rules for making medical devices, needs clean spaces. |

FS 209E | Old U.S. rule, not used now for cleanrooms. |

You should also check for these rules:

EU GMP Annex 1 – Sets rules for making sterile products and cleanroom work.

EN Standards – Local versions of ISO and safety rules.

CE Compliance – Needed for some products to meet system rules.

Amber helps you follow all these rules. You get a cleanroom that passes checks and keeps your work safe. You can trust Amber to help you from planning to getting your certificate.

Note: Picking the right cleanroom and following the rules keeps your staff, patients, and products safe. Amber’s team makes this easy for you.

There are new ways to build cleanrooms now. Some companies let you rent cleanrooms for a short or long time. These rooms are modular, so you can move or change them. Hospitals use modular cleanrooms for making medicine and IVs. Medical device makers use softwall or hybrid cleanrooms for putting things together and packing. CDMOs like pod layouts because they are easy to change. These layouts help you follow different rules.

Renting cleanrooms gives you more choices.

AI systems help you check air quality all the time.

Energy-saving designs help you spend less and protect nature.

Hybrid cleanrooms help you follow many rules.

You can change your cleanroom fast. This helps you keep up with new tech and new rules.

Air cleaning technology is getting better every year. ULPA filters catch very tiny particles. They work better than old HEPA filters. Smart monitors use sensors and IoT devices. These check air quality and change settings by themselves. Automated particle checks help you follow rules without extra work. Fans that save energy and recovery systems help you spend less. Filters with special coatings stop germs and mold from growing.

Technology Type | Description |

|---|---|

Ultra-Low Penetration Air (ULPA) | Catches particles as small as 0.12 microns, better than HEPA. |

Smart Monitoring and Control Systems | IoT devices check air quality and make changes right away. |

Automated Particle Monitoring | Sensors count particles all the time and help you follow rules. |

Energy Efficiency | Fans that change speed and recovery systems use less energy. |

Antimicrobial Coatings | Filters have coatings that stop germs and mold. |

Micro-electrostatic tech also saves energy and lowers costs. You can use these systems in hospitals, drug factories, and food plants.

Smart air cleaning keeps your cleanroom safe and helps you follow health rules.

You can help the earth by picking green cleanroom options. Energy-saving HVAC systems use less power but keep air clean. Green building materials, like special paints and recycled insulation, lower pollution. Water-saving tools and recycling help you use less water. Good waste and recycling plans help you make less trash.

Amber is a leader in green and smart cleanrooms. You get cleanrooms with IoT devices that watch conditions all the time. Amber uses HVAC systems and LED lights that save energy. Eco-friendly materials make your cleanroom safer for people and nature. Robots and smart controls help lower human contact and stop contamination.

Innovation Type | Description |

|---|---|

Smart Cleanrooms | IoT devices watch and control conditions all the time. |

Energy-Efficient Systems | HVAC and LED lights save energy and money. |

Sustainable Materials | Green materials make air better and keep people safe. |

Automation | Robots and smart systems help stop contamination. |

When you pick Amber, you help make healthcare cleaner, safer, and better for the planet.

You can see that medical cleanrooms have different jobs. Each type helps in healthcare or research. The table below shows how they are different:

Type of Cleanroom | Applications | Cleanliness Requirements | Design Features |

|---|---|---|---|

Medical Research Cleanrooms | Used for learning and making new treatments | ISO Class 5-7 | HardWall design |

Medical Device Cleanrooms | Used for making and packing devices | ISO Class 5-8 | HardWall design |

Pharmaceutical Cleanrooms | Used for making medicine and cures | ISO Class 5 or more | Lots of air changes, good coverage |

Amber helps you pick the best cleanroom. They follow strict rules. Their designs help you work better. They use new technology to keep things very clean.

When you choose a cleanroom, think about rules, custom options, and new ideas. Amber’s team helps you find the right cleanroom for your work.

A medical cleanroom is a controlled space. You use it to keep air, surfaces, and equipment free from dust and germs. This helps protect patients and products.

ISO classification tells you how clean the air is. You use it to pick the right cleanroom for your work. It helps you follow safety rules.

Amber listens to your requirements. You get modular designs, custom sizes, and special features. Amber’s team helps you choose the best options for your job.

Amber uses SUS304 stainless steel. You get strong, easy-to-clean surfaces. These materials resist rust and chemicals, making your cleanroom safe and durable.

You use HEPA filters, air showers, and pass boxes. You clean surfaces often. Amber’s systems help you control air and stop germs from spreading.

Yes, you can add modules or move walls. Amber’s modular cleanrooms let you grow or change your space as your needs change.

You see Amber cleanrooms in hospitals, pharmaceutical plants, research labs, dental clinics, and biotech facilities. These spaces need strict contamination control.