- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-12 Origin: Site

A cleanroom is a place where you control dust and germs, which is crucial for protecting products and important work. In 2026, regulations will be very strict, making everything you need to know about cleanrooms even more relevant. New technology is enhancing the importance of cleanrooms, with the global market projected to reach USD 8.10 billion. This growth is rapid due to tougher regulations, as more people require clean and safe spaces.

Compound annual growth rate: 6.8%

Key drivers: government rules, biologics, medicine needs

Description | |

|---|---|

Smart Monitoring Systems | IoT devices monitor the air and room in real time, significantly lowering the chance of contamination. |

Automation and Robotics | Robots handle materials and clean rooms, reducing human contact. |

Advanced Filtration Technologies | New HEPA and ULPA filters enhance air cleanliness and efficiency. |

Material and Surface Innovations | Surfaces are designed to combat germs and self-clean, aiding in germ control. |

Data Analytics and AI | AI optimizes cleanroom operations and compliance, making management more efficient. |

You must learn about planning and regulations to keep your cleanroom safe and functioning effectively. This article provides everything you need to know about cleanrooms, ensuring you are well-prepared and informed.

Cleanrooms keep out dust and germs. This helps products stay safe. It also follows strict rules.

The cleanroom market is growing fast. It may reach USD 8.10 billion by 2026. This growth comes from rules and business needs.

New technology like IoT, automation, and AI helps cleanrooms work better. It also helps people watch over them.

Knowing cleanroom classes and ISO standards is important. It helps you pick the right place for your work.

Cleanrooms need regular tests and care. This keeps them safe and makes sure products are good.

Modular cleanrooms and cleanroom pods are flexible. They save money and help businesses set up quickly.

To future-proof your cleanroom, use strong materials. Add smart technology and plan for upgrades.

Learning about new rules and technology is important. It helps you follow laws and keep products safe.

A cleanroom is a place where air and surfaces stay very clean. Special systems keep dust, germs, and tiny particles out. There are strict rules to stop contamination. Cleanrooms use advanced air filters and have clear standards for cleanliness.

Aspect | Cleanrooms | Controlled Environments |

|---|---|---|

Keep very strict limits on particles | Have lower control over contamination | |

Airflow and Filtration | Use HEPA/ULPA filters and smooth airflow | Use basic air filters |

Cleanliness Standards | Set by allowed particles in each cubic meter | Have easier cleanliness rules |

Cleanrooms have many features to keep things clean:

HEPA filters catch tiny bits in the air.

ULPA filters remove even smaller things.

Airlocks and air showers stop outside dirt from coming in.

Special clothes keep germs from your body out.

Monitors check air and surfaces for cleanliness.

Approved cleaning supplies keep surfaces germ-free.

Cleanrooms are more important in 2026 because industries need safer spaces. Places like medicine, biotech, and electronics use cleanrooms to protect products. Medical device makers need cleanrooms to follow safety rules.

Groups like the FDA and EMA make tough rules for cleanrooms. You must follow these rules to make safe medicines and electronics. More biologics, vaccines, and devices mean you need cleaner places to make them. Electronics companies need super clean rooms so tiny particles do not ruin products.

Component/Feature | Description |

|---|---|

Remove dirty stuff from the air to keep it clean. | |

HVAC Systems | Control temperature and humidity for a safe space. |

Airtight Enclosure | Stops dirty air from getting inside. |

HEPA Filtration | Catches small bits from the air. |

Positive Pressurization | Keeps air pressure higher inside than outside. |

Unidirectional Airflow | Air moves one way to lower contamination risk. |

Cleanrooms help you in many ways. They keep dust, germs, and particles out. You meet strict rules, so your products are safe and legal. Cleanrooms make products better by lowering defects. Fewer bad products means you save money and work faster.

Benefit | Description |

|---|---|

Contamination Control | Cleanrooms keep out dust, germs, and particles. |

They help you follow tough cleanliness rules. | |

Enhanced Product Integrity | Cleanrooms make sure products are high quality. |

Reduced Rejection Rates | Fewer products get thrown away, so you save time and money. |

Cost Efficiency | Cleanrooms help you use materials better and waste less. |

Tip: Always plan your cleanroom to get these benefits. This helps you protect products and follow the rules.

Cleanrooms are needed for industries that want high quality and safety. You use them to keep products pure, follow rules, and save money.

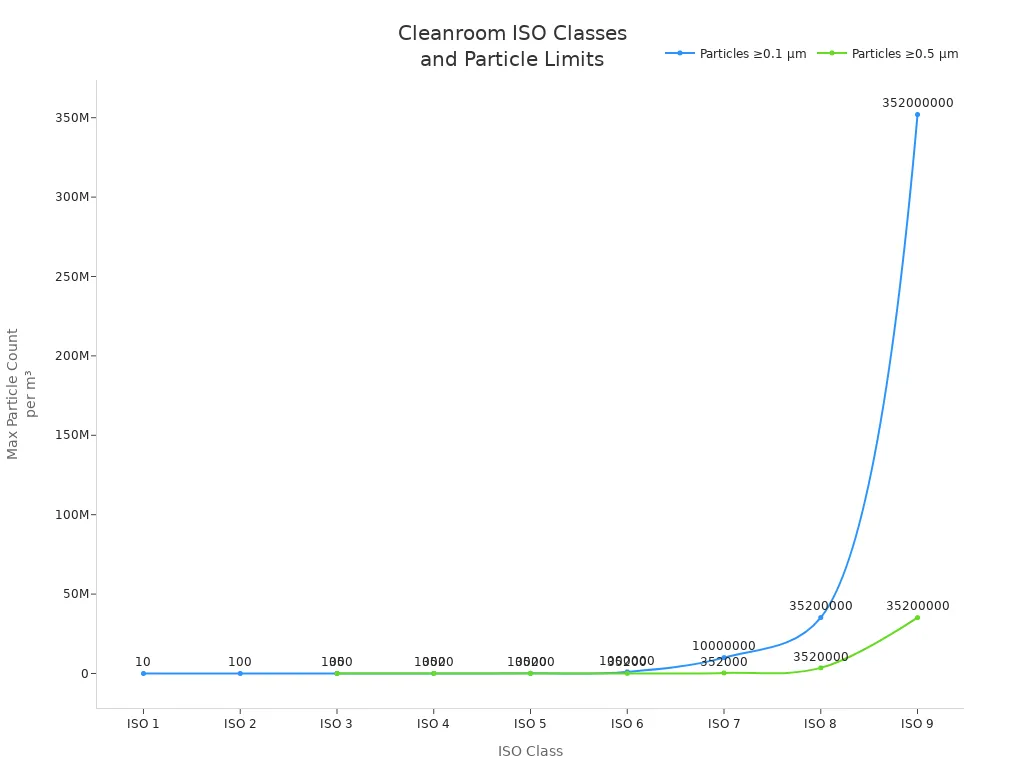

It is important to know about cleanroom classes. Each class has a set limit for tiny particles in the air. If the class number is lower, the room is cleaner. ISO classes go from ISO 1 to ISO 9. ISO 1 lets only 10 particles in each cubic meter. ISO 9 allows up to 352 million particles. This shows how strict each cleanroom can be.

ISO Class | Maximum Particles (≥0.1 µm) | Maximum Particles (≥0.5 µm) |

|---|---|---|

ISO 1 | 10 | — |

ISO 2 | 100 | — |

ISO 3 | 1,000 | 35 |

ISO 4 | 10,000 | 352 |

ISO 5 | 100,000 | 3,520 |

ISO 6 | 1,000,000 | 35,200 |

ISO 7 | 10,000,000 | 352,000 |

ISO 8 | 35,200,000 | 3,520,000 |

ISO 9 | 352,000,000 | 35,200,000 |

Cleanrooms need more than just particle control. Each ISO cleanroom uses special filters and airflow. You also need pressure controls. HEPA or ULPA filters are required. Airlocks and buffer zones help keep dirt out. Higher ISO classes need stricter rules. For example, ISO 5 cleanrooms use more filters and have tougher gowning rules than ISO 8 cleanrooms.

You should look at cleanroom classes before choosing one. ISO 5 cleanrooms are very strict. They are used for important jobs like making medicine. ISO 7 cleanrooms protect ISO 5 areas. ISO 8 cleanrooms are for easier tasks, like putting on cleanroom clothes. The cleanest rooms are in the middle of the building. Less clean rooms are around them. This helps stop contamination and follow rules.

Cleanroom Class | Maximum Particles (≥0.5 µm) per m³ | Role in Manufacturing |

|---|---|---|

ISO 5 | 3,520 | Critical for aseptic processes, ensuring sterility and safety |

ISO 7 | 352,000 | Acts as a protective barrier and staging area for ISO 5 operations |

Tip: Pick the cleanroom class that fits your product. This keeps products safe and helps you follow the rules.

The ISO 14644 standard helps keep cleanrooms up to date. This series covers air monitoring, design, and how to run cleanrooms. Each part has a different job.

Part | Description |

|---|---|

14644-2 | Monitoring requirements for air cleanliness by particle concentration. |

14644-3 | Test methods for maintaining air cleanliness classification. |

14644-4 | Guidelines for design, construction, and startup of cleanrooms. |

14644-5 | Operations requirements for cleanroom management. |

14644-7 | Requirements for separative devices in controlled environments. |

14644-8 | Assessment of air cleanliness for chemical concentration. |

14644-9 | Assessment of surface cleanliness for particle concentration. |

14644-10 | Assessment of surface cleanliness for chemical contamination. |

ISO 5 cleanrooms are used for very important work. They only allow 3,520 particles per cubic meter at 0.5 microns or bigger. You must wear special clothes and use strong filters. Air moves in one direction. You need to check and clean the room often.

ISO 5 cleanrooms are found in places like drug factories, science labs, and electronics plants. These rooms keep products safe from dirt. They help you follow strict safety rules. ISO 5 cleanrooms are used for making sterile drugs, medical devices, and microchips.

Federal Standard 209E is an older rule. It counts particles per cubic foot, not per cubic meter. Some industries still use it, even though ISO 14644 replaced it in 2001.

Feature | ISO 14644-1 | Federal Standard 209E |

|---|---|---|

Measurement Units | Particles per feet cubed (ft³) | |

Historical Context | Defined by ISO, widely used today | Defined by US Government, discontinued in 2001 but still in use |

Industry Relevance | Used by FDA regulated and non-FDA regulated industries | Primarily used in specific industries despite discontinuation |

Different industries use different cleanroom standards. Drug makers use ISO 8 to ISO 5 cleanrooms to follow FDA and GMP rules. Electronics companies use less strict standards. They care more about product quality than health risks.

Industry | Cleanroom Classification | Key Standards and Regulations |

|---|---|---|

Pharmaceuticals | FDA regulations, EU GMP Annex 1, ISO 14644-1, Good Manufacturing Practices (GMP) | |

Electronics | Less stringent | Standards vary, but typically not as strict as pharmaceuticals; focus on preventing costly malfunctions rather than health risks. |

Note: Pick the right cleanroom class for your industry. This helps you avoid problems and fines.

Most industries now use ISO 14644 instead of FS209E. ISO standards are used all over the world. They help you follow international rules. Use ISO 14644 for new cleanrooms to stay up to date.

Cleanroom rules are changing a lot in 2026. The iso 5 cleanroom now has tougher rules for air and particles. The iso 14644 series has new updates for real-time checks. You need sensors to watch air and particle levels all the time. Groups like the FDA and EPA want better records. You must show your cleanroom follows iso rules. These changes help keep products safe and protect people.

Standard Update | What You Need to Know |

|---|---|

ISO 14644 revisions | You must track data in real time now |

Federal rules | You need digital records and clear audit trails |

ISO 5 cleanroom rules | There are stricter particle limits and more tests |

Note: Always look for new iso updates before you build or change your cleanroom.

In 2026, you have new rules for your cleanroom. Many industries want digital tracking for compliance. You need IoT devices in your iso 5 cleanroom. These devices check air, temperature, and humidity. They send alerts if something is wrong. You must keep records that cannot be changed, often with blockchain. This helps you pass audits and show your cleanroom meets iso rules.

Drug and electronics companies want portable testing units. You can use these to check your iso 5 cleanroom fast. You do not have to wait for lab results. This saves time and helps you fix problems quickly.

You will see new trends in cleanroom classes in 2026. Here are some important ones:

IoT sensors let you spot problems early.

Predictive analytics help you plan cleanroom fixes and avoid downtime.

Flexible cleanroom designs help you follow new iso rules fast.

Blockchain keeps your records safe for audits.

Portable testing units let you check your cleanroom on site.

Tip: To keep your iso 5 cleanroom up to date, use these tools and follow new iso standards.

You need to follow these changes to keep products safe and meet world rules. The iso 5 cleanroom is smarter and safer now. You can use new tech to make sure your cleanroom always meets iso standards.

It is important to know how air moves in a cleanroom. Laminar airflow goes in straight lines. It pushes particles away from important spots. This airflow is best for places where you cannot have any contamination, like ISO Class 3 cleanrooms. Laminar systems can lower particle numbers by almost 99.99%. These systems use more energy, sometimes half again as much as others.

Turbulent airflow mixes air in every direction. This helps spread and remove contaminants fast. You see turbulent airflow in ISO Class 5 to Class 8 cleanrooms. These systems use less energy and still remove most particles, about 90-95%. Use laminar airflow for the cleanest rooms. Use turbulent airflow for rooms that need quick air changes.

Airflow Type | Cleanliness Level | Energy Efficiency | Particle Reduction |

|---|---|---|---|

Laminar | ISO Class 3 and cleaner | Higher energy consumption | Up to 99.99% reduction |

Turbulent | ISO Class 5 to Class 8 | Lower energy consumption | 90-95% reduction |

Tip: Laminar airflow protects your most sensitive products. Turbulent airflow saves energy in less important areas.

Air change rate means how many times the air gets replaced each hour. More air changes make the room cleaner. You need to match the air change rate to your cleanroom’s needs. ISO 1 and ISO 2 cleanrooms need 500 to 750 air changes every hour with unidirectional airflow. ISO 5 cleanrooms need 240 to 480 changes per hour. ISO 8 cleanrooms only need 5 to 48 changes per hour.

Cleanroom Classification | Air Change Rate (ACH) | Required Airflow Type |

|---|---|---|

ISO 1 | 500 to 750 | Unidirectional |

ISO 2 | 500 to 750 | Unidirectional |

ISO 3 | 360 to 540 | Mostly unidirectional |

ISO 4 | 300 to 480 | Mixed |

ISO 5 | 240 to 480 | Mixed |

ISO 6 | 150 to 240 | Turbulent |

ISO 7 | 60 to 90 | Turbulent |

ISO 8 | 5 to 48 | Turbulent |

ISO 9 | Less than 5 | Standard HVAC |

Always check your air change rates. This keeps your cleanroom safe and meets requirements.

Filtration is very important for cleanrooms. HEPA filters catch tiny particles, as small as 0.3 microns. ULPA filters catch even smaller ones. Cleanrooms use several filters together, like pre-filters, HEPA, and ULPA, to trap all sizes of contaminants. Some cleanrooms use special filters for chemicals or germs.

Filtration Type | Description |

|---|---|

Multi-stage filtration systems | Use pre-filters, HEPA, and ULPA filters for all particle sizes. |

Airflow management and distribution | Place air outlets for even airflow. |

Monitoring and control systems | Use sensors for real-time air quality checks. |

Energy-efficient designs | Use variable speed fans and heat recovery systems. |

Specialized filtration | Target specific contaminants like VOCs and microorganisms. |

You need to keep your filters clean and working well. Change HEPA filters every three to five years. Change ULPA filters every two to three years. If your cleanroom runs all the time, you may need to change filters more often. Test your filters for leaks every six to twelve months. This keeps your cleanroom safe and helps you follow ISO 14644-3 rules.

Change HEPA filters every 3-5 years.

Change ULPA filters every 2-3 years.

Test for leaks every 6-12 months.

Note: Checking filters often helps you stop contamination and keeps your cleanroom working well.

Controlling temperature and humidity is very important. Most cleanrooms stay at 70°F (21°C) with only small changes. Relative humidity should be between 30% and 40%. Aerospace cleanrooms use temperatures from 67°F to 77°F and humidity from 40% to 60%. ISO Class 1 to Class 5 cleanrooms need temperatures from 64°F to 72°F and humidity from 30% to 60%. Pharmaceutical cleanrooms keep temperatures from 64°F to 77°F and humidity from 30% to 65%.

Keep humidity between 30-40% all year.

Keep temperature at 70°F (21°C) with a 2-degree change.

Adjust for special needs, like aerospace or pharmaceuticals.

You must control air pressure in your cleanroom. Higher pressure inside keeps dirty air out. This protects your products and helps you meet requirements. Use sensors to watch pressure and change it when needed.

Tip: Always check temperature, humidity, and pressure. This keeps your cleanroom safe and helps you follow the rules.

You must pick the right surfaces and materials for your cleanroom. These choices help keep dust and germs out. Smooth surfaces work best because they do not hold dirt. Non-porous surfaces do not let bacteria hide. You should use materials that do not rust or break down. They should not make static and must be easy to clean.

Common materials for cleanrooms are:

Aluminum, plastic, and stainless steel are good because they do not rust. They are easy to wipe clean.

Chrome-plated metal is strong and lasts a long time.

Epoxy paint for walls and ceilings does not burn, get wet, or grow mold.

Hydrophobic floors do not let water in. They resist damage and rust.

Windows are sealed tight. Some have sloped sills so dust and water do not build up.

Doors have no cracks. Some can lock together to keep out dirt.

Tip: Always pick materials that meet cleanroom rules. This helps you stop hidden dust and makes cleaning simple.

You also need special tools and supplies in the cleanroom. Use wipes, mops, and cleaners that do not leave lint. Pick notebooks, pens, and tape made for cleanrooms. These items help keep the space safe and stop contamination.

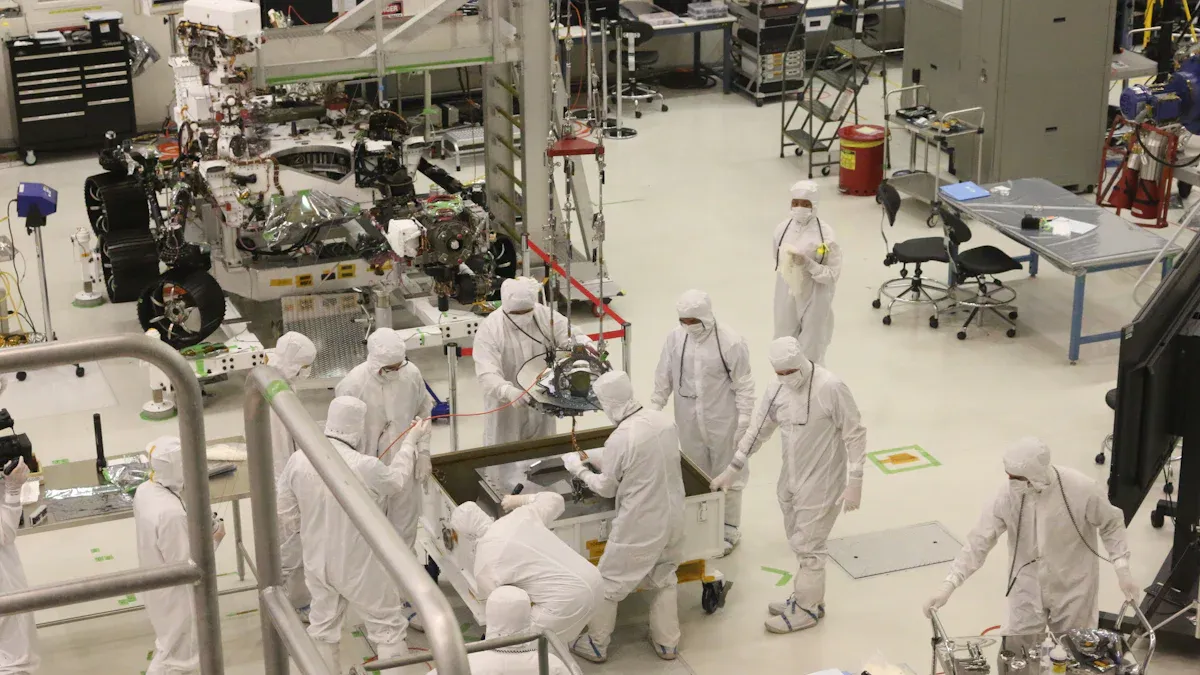

You help keep the cleanroom clean. Before you go in, you must follow special steps. You put on hair covers, masks, gloves, gowns, and shoe covers in order. The order matters because it stops dust and germs from coming in.

Here are the main steps:

Wash up before work. Do not wear makeup or lotion.

Put on cleanroom clothes in the right order. Do not skip steps.

Move slowly inside the cleanroom. Fast moves stir up dust.

Only trained people can enter. This keeps the room safe.

Clean surfaces and tools often. Follow the cleaning plan.

Note: Small mistakes, like touching your face or moving fast, can bring lots of particles into the cleanroom.

You need training to learn these steps. Training teaches you about hygiene, stopping contamination, and why rules matter. Your actions help keep the cleanroom safe and protect products.

You need a cleanroom to make safe medicine and vaccines. In this field, you must stop germs and tiny particles. You use special machines for sterilizing and materials that do not rust. Workers wear clean clothes and follow hygiene steps. Health checks for workers happen a lot. You must follow Good Manufacturing Practices (GMP) rules. These rules limit germs and particles in the air. You keep the temperature and humidity steady to protect products.

You use a cleanroom to build microchips and electronic parts. Dust and static can ruin these products. You need precise machines and anti-static materials. Workers wear anti-static clothes and follow cleaning steps. You follow SEMI standards to keep out dust and control static. You control both tiny particles and molecules in the air. You use special filters and airflow to keep the room clean. You check the air often to make sure it is safe for electronics.

Here is a table that shows how cleanroom needs are different in the pharmaceutical and semiconductor industries:

Aspect | Semiconductor Cleanroom | Pharmaceutical Cleanroom |

|---|---|---|

Equipment and Materials | High-precision machines, low-dust, anti-static materials | Production lines, sterilization equipment, corrosion-resistant materials |

Personnel Management | Anti-static clothing, strict purification procedures | Clean garments, hygiene procedures, regular health checks |

Design Standards | SEMI standards, stringent particulate control | GMP standards, limits on microorganisms and particles |

Environmental Control Focus | Control of particulate and molecular contaminants | Control of microbial contamination, temperature, and humidity |

Tip: Always design your cleanroom for your industry’s needs. This helps you protect products and follow the rules.

You use a cleanroom to make medical devices like implants and tools. These products must stay free from germs and dust. You follow cleaning and sterilizing steps. You use special machines to test for contamination. Workers wear clean clothes and follow hygiene rules. You keep the air clean with strong filters. You check surfaces and tools often. You follow rules from groups like the FDA to keep devices safe for patients.

Each industry uses a cleanroom in its own way. You must know your industry’s rules and needs before you plan your cleanroom. This helps you make safe products and meet all requirements.

You need a cleanroom in aerospace and defense to build and test sensitive equipment. Even tiny bits of dust can hurt satellites or military electronics. Cleanrooms are used to put together sensors and guidance systems. These rooms stop contamination that could ruin a mission. You control the temperature, humidity, and air pressure to protect important materials. Workers wear special suits and follow strict rules to enter. Advanced filters and airflow systems keep the air very clean.

In this field, you work with materials that must stay dust-free and static-free. Stainless steel benches and smooth surfaces help stop particles from sticking. You test parts for cleanliness before sending them to space. Cleanrooms are also used to check and fix satellites after they come back. These rooms help you follow tough rules from NASA and the Department of Defense. These rules make sure your projects are safe and work well.

Tip: Always check your cleanroom for leaks or pressure changes. This helps you avoid expensive mistakes in aerospace and defense work.

You use a cleanroom in food and beverage to keep products safe and fresh. Cleanrooms stop bacteria, mold, and dust from getting into food. This happens during packaging and processing. You control air quality, temperature, and humidity to protect foods like dairy and baked goods. Workers wear hairnets, gloves, and gowns to keep out germs.

Special equipment is easy to clean and does not rust. Floors and walls are smooth so you can wash them often. Airlocks and pressure controls keep outside air from coming in. Cleanrooms help you follow food safety rules from the FDA and USDA. These rules keep customers safe and help you avoid recalls.

Note: Cleaning and testing your cleanroom often keeps food safe and helps you pass inspections.

In 2026, cleanrooms are used in many new fields. You find them where you must control even tiny particles or germs. Here are some of the newest uses:

Biotechnology: Cleanrooms are used to make gene therapies and CAR-T cancer treatments. These treatments save lives and need very clean spaces.

Nanotechnology: You build quantum computers and new materials in cleanrooms. Tiny particles can ruin these high-tech products.

Clean technology: You make solar panels and lithium batteries in cleanrooms. Clean air helps you build better and safer power sources.

Research: You develop vaccines for pandemics and make semiconductors for self-driving cars. Cleanrooms keep these products pure and working well.

Cleanrooms now help many industries, not just the old ones. As technology grows, you will see even more uses for cleanrooms in the future.

You can pick modular clean rooms if you want a fast, flexible option. These cleanrooms use parts made ahead of time. This means you can set them up quickly and change them easily. If your company grows, you can make the cleanroom bigger or change its shape. You do not need to build a whole new room. You save time and money because you do not have to stop work for long.

Here is a table that shows how modular clean rooms are different from traditional cleanrooms:

Aspect | Modular Cleanrooms | Traditional Cleanrooms |

|---|---|---|

Maintenance | Easier to clean and fix | Harder to keep up, needs more checks |

Customization | Easy to change with little trouble | Hard to change, needs big work |

Installation Speed | Quick, because parts are ready | Slow, uses old building ways |

Cost | Costs less over time | Costs more in the long run |

You can also use portable modular clean rooms if you need a clean space in more than one place. These rooms can move or be set up in new spots fast. You still get the same clean air and control as in a regular cleanroom.

Cleanroom pods give you even more choices. These pods come ready to use with air, filters, and controls already inside. You can use cleanroom pods right away because they are built in a factory. You do not have to wait for building at your site. If you need something different, you can move or use the pods somewhere else.

Here is a table that shows how cleanroom pods and modular clean rooms are not the same:

Feature | Cleanroom Pods | Modular Cleanrooms |

|---|---|---|

Deployment Speed | Very fast, made in a factory | Slower, needs to be put together on site |

Flexibility | Easy to change and use again | Not as easy to change |

Scalability | Simple to make bigger | Might need big changes to grow |

Integration | Has built-in systems | Needs help from other companies |

Cost Efficiency | Saves money over time | Costs more at first and later |

You can use cleanroom pods for short jobs, research, or when you need a clean space fast. These pods help you follow tough rules and keep your products safe.

You get many good things when you use modular clean rooms or cleanroom pods:

You set up your cleanroom fast and start working sooner.

You can change, grow, or move your cleanroom as your needs change.

You spend less on fixing things because you can reach parts easily.

You can make your cleanroom fit your needs.

You meet ISO and other rules with less work.

Tip: If you think your building will change, modular clean rooms and cleanroom pods help you adjust fast and save money.

You can use these cleanrooms in many fields, like medicine, electronics, and food. You keep your products safe and follow all the rules with less trouble.

You can turn an existing room into a cleanroom without starting from scratch. Retrofitting gives you a smart way to create a controlled environment quickly. Many businesses choose this method because it saves money and time compared to building a new space. You do not need to wait for long construction projects. You can adapt your space to new technology and rules with less effort.

When you retrofit, you use what you already have. You add cleanroom pods or modular clean rooms to your current building. These solutions fit into offices, warehouses, or labs. You do not need to tear down walls or change the whole layout. You can install cleanroom pods in corners, unused rooms, or even large open areas. This flexibility helps you meet new standards fast.

Here are some steps you can follow when retrofitting:

Check your current space for size, airflow, and power.

Choose cleanroom pods or modular clean rooms that fit your needs.

Install air filters, pressure controls, and special surfaces.

Train your team to use the new cleanroom safely.

Test the space to make sure it meets cleanliness rules.

You can see big benefits when you retrofit. You spend less money because you use your existing building. You finish the project faster, so you start working sooner. You can change or move cleanroom pods if your needs grow. This makes your business ready for new products or rules.

Retrofitting Benefit | Description |

|---|---|

Cost Savings | You avoid high costs of new construction |

Time Savings | You set up cleanroom pods quickly |

Flexibility | You can move or change cleanroom pods easily |

Compliance | You meet new standards without major changes |

Cleanroom pods work well for retrofitting because they come ready to use. You do not need special tools or long building times. You can add more cleanroom pods as your business grows. Modular clean rooms also help you expand or change your space without big projects.

Tip: Always check your building for leaks or weak spots before you add cleanroom pods. This helps you keep the space safe and clean.

Retrofitting lets you keep up with new technology and rules. You can use cleanroom pods to protect your products and meet industry standards. Modular clean rooms give you options to grow and change as your needs shift. You make your workspace safer and more efficient with these solutions.

Modern cleanrooms have many smart features. These features help keep your space safe and working well. In 2026, you use technology to watch your cleanroom all the time. You can spot problems early with real-time checks. Wireless sensors check air, temperature, and humidity. You use portable tools to get data from anywhere in the cleanroom. AI analytics help you make fast choices. These tools show patterns and warn you about dangers.

IoT lets you watch your cleanroom right away.

AI analytics help you understand data and follow iso rules.

Wireless sensors gather information fast and correctly.

Portable tools let you check your cleanroom in many ways.

You use automation and remote checks to save time. These systems help you grow your cleanroom and meet iso rules. You work to stop contamination before it starts. Predictive maintenance keeps your cleanroom working without problems.

IoT and automation make your cleanroom smarter. IoT systems watch your cleanroom all day and night. They check air, pressure, and particle levels. You get alerts if something is wrong. Automation helps you keep records for iso audits. You do not need to write reports by hand anymore. Automated systems lower mistakes and save time.

Aspect | Description |

|---|---|

Real-time Monitoring | IoT systems check your cleanroom to help you meet iso standards. |

Automation | Automated records make iso audits and reports easier. |

Integration with HVAC | IoT adjusts airflow and filtration to keep your cleanroom safe and efficient. |

IoT and automation give you many good things. You get audit trails that help you pass iso checks. Automated reports lower errors and make checks faster.

Benefit | Description |

|---|---|

Audit Trails | Automated systems give you proof for iso inspections. |

Error Reduction | Automated reports help you avoid mistakes during iso compliance checks. |

You use these tools to keep your cleanroom safe and follow iso rules every day.

You want your cleanroom to use less energy and make less waste. Sustainable design helps you reach iso goals and protect nature. You pick fans and smart HVAC systems that save power. IoT sensors help you change airflow and temperature to use less energy. You use strong materials that are easy to clean. You recycle air and water when you can. You plan your cleanroom to use space well and save money.

Tip: Pick green options to meet iso rules and help the earth.

More companies use green building for cleanrooms now. You meet iso rules and show you care about the future. You make your cleanroom safer, smarter, and better for everyone.

In 2026, there are new ways to build cleanrooms. These advanced construction methods help you follow strict iso standards. They also help you finish your project faster. You can save money and make your cleanroom safer. These methods keep your cleanroom modern.

Prefabrication and Modular Building

You can pick prefabricated panels and modular parts. Factories make these under iso rules. Workers bring them to your site and put them together fast. This way, you make fewer mistakes. Your cleanroom stays cleaner while building. There is less dust and fewer delays.

3D Modeling and BIM (Building Information Modeling)

You use 3D modeling tools to plan your cleanroom. BIM software lets you see every part before building. You can check airflow, pressure, and iso rules in the model. This helps you find problems early. You save time and avoid expensive changes later.

Seamless Surfaces and Welded Joints

You choose seamless walls, floors, and ceilings. These surfaces stop dust and germs from hiding. Welded joints make sure nothing leaks. You meet iso rules for easy cleaning and strong barriers.

Rapid Assembly Techniques

You use snap-fit systems and quick-lock panels. These let you build or change your cleanroom fast. You can add rooms or move walls without long stops. This helps you keep up with new iso rules.

Smart Integration with Building Systems

You connect your cleanroom to smart HVAC, lighting, and monitoring systems. These systems follow iso standards for air and safety. You can control everything from one place. Sensors check temperature, humidity, and pressure all the time.

Construction Method | Benefit for You | iso Impact |

|---|---|---|

Prefabrication | Faster build, less mess | Meets iso cleanliness |

BIM and 3D Modeling | Better planning, fewer errors | Checks iso compliance |

Seamless Surfaces | Easy to clean, stops germs | Supports iso cleaning |

Rapid Assembly | Quick changes, less downtime | Adapts to iso updates |

Smart Integration | Full control, real-time monitoring | Tracks iso conditions |

Tip: Always ask your builder if their methods meet the latest iso standards. This keeps your cleanroom safe and ready for audits.

You can use these advanced construction methods to build a cleanroom that meets every iso rule. You get a safer, smarter, and more flexible space for your work.

You have to test your cleanroom often to keep it safe. Testing helps you find problems before they hurt your work. You use different ways to check the air, surfaces, and equipment.

You use airborne particle counting to see how many tiny bits are in the air. This test shows if your cleanroom meets ISO rules. You walk around with a particle counter and check many places. If you find too many particles, you must fix it fast.

You need to see how air moves in your cleanroom. Airflow visualization, or smoke testing, lets you watch air with special smoke. You look for spots where air does not move well. These places can collect dust and germs. You also check airflow and pressure with tools to make sure air moves right.

Airflow and pressure testing checks air speed and pressure changes.

Smoke testing shows how air moves and helps you find problem spots.

Room recovery testing tells you how fast your cleanroom gets back to safe levels after a problem.

You must check for germs and bacteria in your cleanroom. You use plates or swabs to test air and surfaces. If you find too many germs, you clean the area and test again. This keeps your products safe and helps you follow the rules.

The main goal of these tests is to show that everything in the cleanroom—from air to equipment and surfaces—does not bring in contamination that could hurt the process or the final product.

You need to prove your cleanroom works the right way. Certification has three main steps:

Installation Qualification (IQ): You check that all equipment and the room match the plans.

Operational Qualification (OQ): You test the cleanroom while it runs to see if it works right.

Performance Qualification (PQ): You watch the cleanroom over time to make sure it stays safe.

You must keep records of every test and result. These papers help you pass audits and show you follow ISO rules.

You keep your cleanroom safe by following a regular maintenance plan. Here is a simple schedule:

Frequency | |

|---|---|

Daily | Make sure alerts for airflow, pressure, and particles are working. |

Weekly | Check for damage or problems with equipment; calibrate sensors and monitors if needed. |

Monthly | Look at reusable gowns and suits; check cleaning and maintenance logs; test filters. |

Quarterly | Check the building for problems; check pressure; test equipment. |

Annually | Do a full cleanroom certification; change filters; check maintenance plans; inspect HVAC systems. |

You follow this plan to keep your cleanroom working well and meeting all standards.

You start by figuring out what you need from your cleanroom. Think about the products you make and the rules you must follow. You look at how clean the air must be and how many people will work inside. You decide if you need special equipment or extra safety steps. You check if your work needs a very strict cleanroom or if a basic one will do.

Ask yourself these questions:

What products will you make or test?

How clean does the air need to be?

How many workers will use the space?

Do you need special machines or tools?

What rules must you follow for your industry?

You write down your answers. This list helps you plan the right cleanroom for your job.

You need to know how much money you will spend. Cleanrooms can cost a lot, so you plan your budget early. You look at the price for building, equipment, and keeping the room clean. You also think about costs for testing and following rules.

Here is a table to help you see the main costs:

Cost Type | What It Covers |

|---|---|

Construction | Building walls, floors, and ceilings |

Equipment | Filters, HVAC, and monitors |

Maintenance | Cleaning, repairs, and filter changes |

Testing | Air checks and safety inspections |

Compliance | Meeting ISO and other standards |

You save money by picking the right size and type of cleanroom. You also look for energy-saving options and easy-to-clean surfaces.

Tip: Always add extra money in your budget for surprise costs. This helps you avoid problems later.

You get help from experts when you plan your cleanroom. These experts know the rules and best ways to build. They help you pick the right design and equipment. You talk to engineers, builders, and safety teams. You ask questions and share your needs.

Experts help you:

Understand ISO standards and other rules

Choose the best layout for your space

Find good materials and equipment

Train your team to use the cleanroom safely

You work with experts from the start. This makes your project easier and helps you avoid mistakes.

You want your cleanroom to stay useful and safe for many years. Planning for the future helps you avoid costly changes and keeps your work running smoothly. You can use smart strategies to make sure your cleanroom meets new rules and technology.

Here are some ways to future-proof your cleanroom:

Choose Flexible Designs

You can pick modular walls and ceilings. These parts let you change the size or layout when your needs grow. You do not need to rebuild everything. You save time and money.

Use Smart Technology

You can install sensors that watch air, temperature, and humidity. These sensors send alerts if something goes wrong. You can add new sensors later if rules change. Smart systems help you keep up with new standards.

Plan for Upgrades

You can leave space for new machines or extra equipment. You can add more power outlets and data ports. You do not need to move walls or change the whole room. Planning ahead makes upgrades easy.

Pick Durable Materials

You can use strong surfaces that resist damage and are easy to clean. Materials like stainless steel and epoxy last a long time. You spend less on repairs and replacements.

Train Your Team Regularly

You can teach your team about new rules and best practices. Regular training helps everyone follow safety steps. You lower the risk of mistakes and keep your cleanroom safe.

Tip: Review your cleanroom plan every year. You can spot problems early and fix them before they get big.

Table: Future-Proofing Strategies

Strategy | Benefit | How It Helps You |

|---|---|---|

Flexible Design | Easy to change or expand | Adapts to new needs |

Smart Technology | Real-time monitoring | Meets new standards |

Upgrade Planning | Space for new equipment | Quick upgrades |

Durable Materials | Long-lasting surfaces | Fewer repairs |

Team Training | Up-to-date skills | Fewer mistakes |

You can also talk to experts about future trends. They know about new rules and technology. You can ask them for advice before you make big changes.

You protect your investment when you plan for the future. Your cleanroom stays ready for new products, rules, and technology. You keep your work safe and your business strong.

You now know a lot about cleanrooms, new rules, and smart tech for 2026. If you want to build or make your cleanroom better, remember these facts before you begin. You should look for new updates often because rules can change fast. Always talk to experts and check the latest information to keep your cleanroom safe.

Tip: Keep learning about cleanrooms. This helps you keep your products safe and follow the rules.

You use a cleanroom to keep dust, germs, and other particles away from products. This helps you make safe and high-quality items in fields like medicine, electronics, and food.

You should test your cleanroom at least once a year. Some industries need more frequent checks. Always follow your industry’s rules for testing and monitoring.

Yes, you can retrofit an existing space. You add special filters, surfaces, and controls. This helps you meet cleanroom standards without building a new room.

HEPA filters catch particles as small as 0.3 microns. ULPA filters trap even smaller particles, down to 0.12 microns. You choose the filter based on your cleanroom’s needs.

Special clothing stops hair, skin, and germs from entering the cleanroom. You protect products and keep the space clean by wearing gowns, gloves, and masks.

You use smart HVAC systems, LED lighting, and variable speed fans. IoT sensors help you control airflow and temperature. These steps lower energy use and save money.

You must find the problem and fix it right away. You may need to clean, change filters, or adjust airflow. Always retest to make sure your cleanroom meets standards.

You see cleanrooms in pharmaceuticals, electronics, medical devices, aerospace, and food production. New fields like nanotechnology and clean energy also use cleanrooms.