- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-11 Origin: Site

You use ISO cleanroom classifications to keep air clean. This helps stop contamination in places where products are made or studied. Each class, from ISO 1 to ISO 9, has strict rules for particles. These rules help you keep products safe and follow industry rules. The Different Cleanroom Types (ISO 1 to ISO 9) show how clean a room is. This makes it easier for you to pick the best place for your work.

Industry | |

|---|---|

Pharmaceuticals | ISO Class 5 to 8 |

Microelectronics | ISO Class 3 to 5 |

Medical Devices | ISO Class 7 and 8 |

Aerospace | ISO Class 5 through 8 |

Food Processing | Not always ISO-classified |

Research Labs | ISO Class 5 to 8 |

Picking the right ISO class helps you make better products. It also helps you follow important rules. Cleanroom standards help you design rooms, pick equipment, and train workers. These steps help stop contamination.

You must check cleanroom classifications to meet cleanliness rules.

Government groups want clean rooms during your facility’s life.

Cleanrooms set limits for particles in the air to keep products safe.

ISO cleanroom classifications go from ISO 1 to ISO 9. Each class has rules for how many particles can be in the air. These rules help stop contamination.

Picking the right ISO class is very important. It keeps products safe and follows industry rules. This matters a lot in areas like medicine and electronics.

ISO Class 1 is the cleanest. It only allows 10 particles in each cubic meter. ISO Class 9 lets in up to 35,200,000 particles. ISO Class 9 works for jobs that are not very sensitive.

Checking and fixing air quality often is needed. This helps meet cleanroom rules and keeps products safe.

Different jobs need different levels of cleanliness. Medicine usually needs ISO Class 5. Food factories might use ISO Class 8.

Getting the right cleanroom class can save money later. It stops contamination and keeps products safe.

Always look at industry rules and standards like ISO 14644-1. This helps you pick the cleanroom class you need.

Training workers well and cleaning carefully are very important. These steps help keep cleanroom rules and stop contamination.

If you want to control air quality, you need to know about ISO 14644-1. This standard gives the rules for iso cleanroom classifications. It explains how to check and limit particles in the air. Special particle counters are used to find particles from 0.1 to 5 micrometers. These numbers help you figure out your cleanroom class. This keeps your products safe and helps you follow industry rules.

You pick a cleanroom type based on how clean the air must be. Some jobs, like microelectronics or pharmaceuticals, need very clean air. This protects products that are easy to damage. Other jobs can have more particles in the air. Choosing the right iso cleanroom classifications stops contamination and meets the law. You also save money by not making your cleanroom too clean. When you match the cleanroom to your needs, you protect your products and your business.

Tip: Always check what your industry needs before you build or change a cleanroom. This helps you avoid spending too much money by mistake.

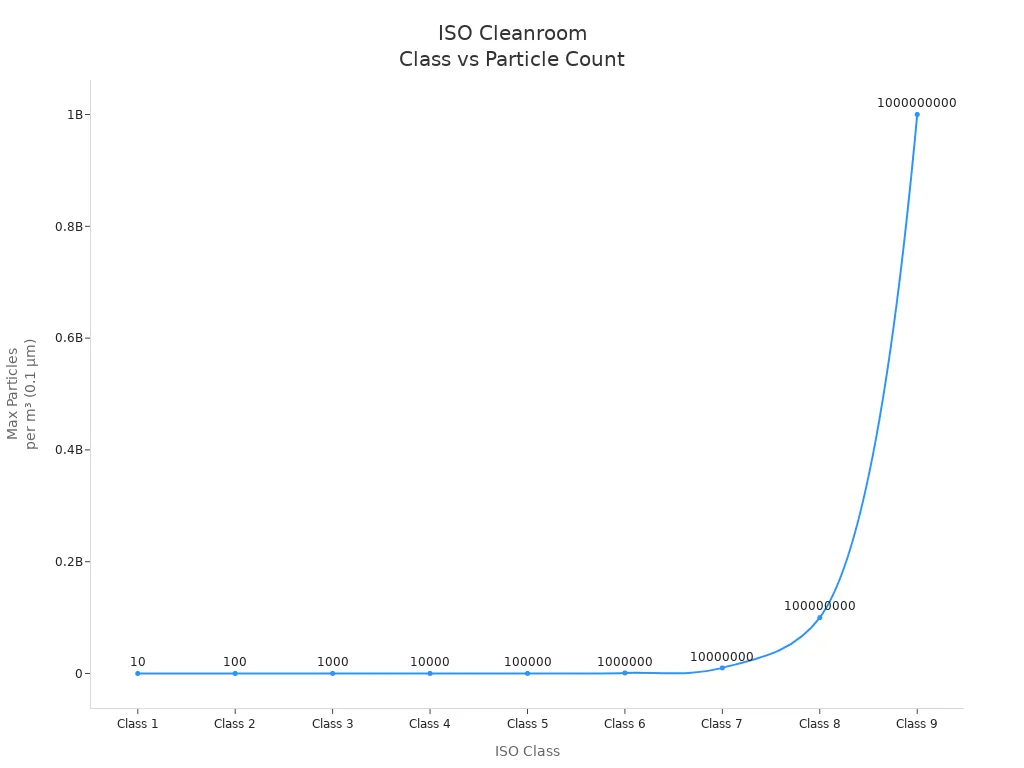

ISO cleanroom classifications use a logarithmic scale for particle limits. Each class lets in ten times more particles than the one above it. For example, ISO Class 1 allows only 10 particles per cubic meter. ISO Class 2 allows 100. The jump between classes is very big. You need to watch these numbers when you plan or use a cleanroom.

Here is a table that shows how the particle limits go up for each class:

ISO Class | Maximum Particles (0.1 µm) per m³ | Allowable Increase |

|---|---|---|

Class 1 | 10 | 10 times |

Class 2 | 100 | 10 times |

Class 3 | 1,000 | 10 times |

Class 4 | 10,000 | 10 times |

Class 5 | 100,000 | 10 times |

Class 6 | 1,000,000 | 10 times |

Class 7 | 10,000,000 | 10 times |

Class 8 | 100,000,000 | 10 times |

Class 9 | 1,000,000,000 | 10 times |

The table and chart show that moving up a class changes air quality a lot. You must choose the right class for your product. This keeps your work safe and helps you do your job well.

You see the strictest standards in iso class 1. This type sets the highest bar for cleanliness among the different cleanroom types (iso 1 to iso 9). You find iso 1 cleanroom environments in places where even a single particle can ruin a product. Semiconductor manufacturing, nanotechnology, and advanced biotechnology research need this level of control. You must keep the air almost completely free of particles. Iso class 1 allows only 10 particles per cubic meter at 0.1 microns or larger. This means you need advanced filtration and constant monitoring.

ISO Class | ≥ 0.1 µm/m³ | ≥ 0.2 µm/m³ | ≥ 0.3 µm/m³ | ≥ 0.5 µm/m³ | ≥ 1 µm/m³ | ≥ 5 µm/m³ |

|---|---|---|---|---|---|---|

ISO 1 | 10 | 2 | 1 | 0 | 0 | 0 |

You must use special equipment and strict protocols to reach iso class 1 standards. Even the smallest mistake can lead to contamination.

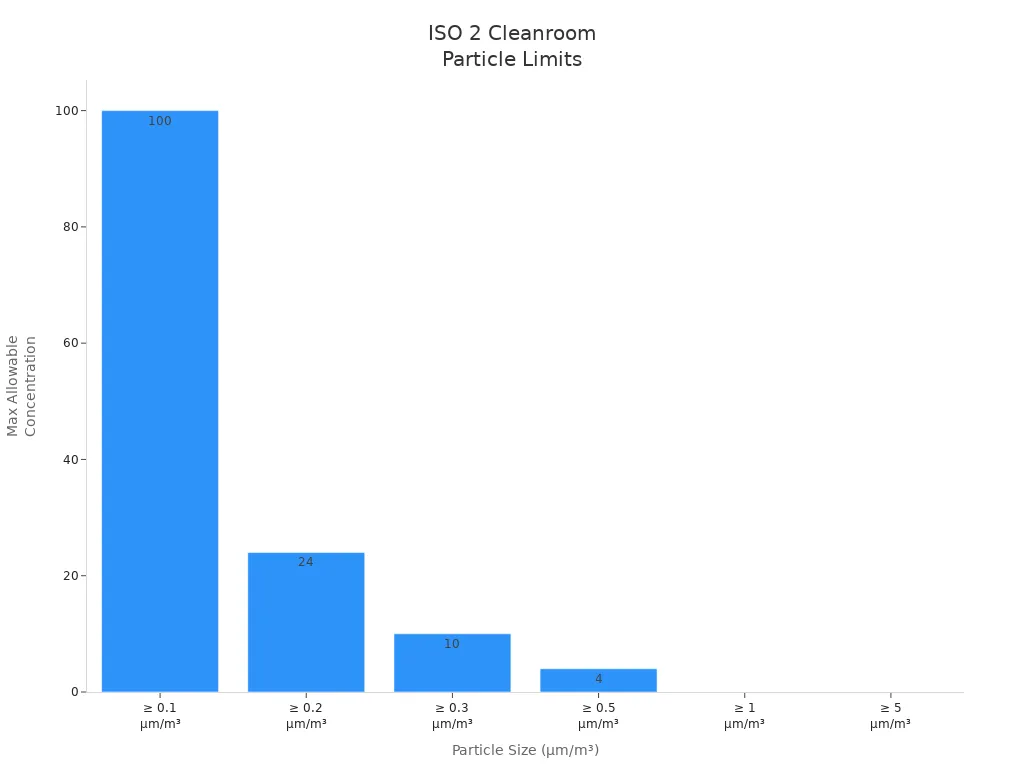

You step down slightly in cleanliness with iso class 2. This class still belongs to the most demanding group in the different cleanroom types (iso 1 to iso 9). Iso class 2 lets in up to 100 particles per cubic meter at 0.1 microns. You see this class in high-precision electronics and optics manufacturing. You need advanced air filtration and regular particle counting.

ISO Class | ≥ 0.1 µm/m³ | ≥ 0.2 µm/m³ | ≥ 0.3 µm/m³ | ≥ 0.5 µm/m³ | ≥ 1 µm/m³ | ≥ 5 µm/m³ |

|---|---|---|---|---|---|---|

100 | 24 | 10 | 4 | 0 | 0 |

You must check particle levels often. Iso class 2 cleanrooms use advanced filtration and airflow systems to keep the air clean.

You notice a shift in requirements with iso class 3. This class allows up to 1,000 particles per cubic meter at 0.1 microns. Iso class 3 stands as a key step in the different cleanroom types (iso 1 to iso 9). You find this class in microelectronics, pharmaceutical manufacturing, and some aerospace applications. You need ultra-low penetration air (ULPA) filters and hundreds of air changes per hour.

Cleanroom Class | Particles > 0.3 microns | Particles > 1.0 microns | Particles > 5.0 microns |

|---|---|---|---|

ISO Class 3 | < 102 | ≤ 8 | N/A |

You see iso class 3 cleanrooms use ULPA filtration.

You need 500-750 air changes per hour to maintain this level.

Iso class 3 gives you a balance between strict particle control and practical operation. You must follow careful cleaning and monitoring routines.

You see that the different cleanroom types (iso 1 to iso 9) offer a wide range of particle limits. You must choose the right class for your work to protect your products and meet industry standards.

Iso class 4 is very clean but not the strictest. You use it for advanced electronics and optics. Some pharmaceutical work needs this class too. Iso class 4 lets in up to 10,000 particles per cubic meter at 0.1 microns. You need strong air filters. People and equipment must be clean before entering.

ISO Class | ≥ 0.1 µm/m³ | ≥ 0.2 µm/m³ | ≥ 0.3 µm/m³ | ≥ 0.5 µm/m³ | ≥ 1 µm/m³ | ≥ 5 µm/m³ |

|---|---|---|---|---|---|---|

ISO 4 | 10,000 | 2,400 | 1,000 | 400 | 40 | 0 |

You wear special clothes and follow strict cleaning steps in iso class 4. This keeps tiny particles away from your products.

Iso class 5 cleanrooms keep particle counts very low. Many industries use this class for important jobs. You see iso class 5 in making semiconductors and medical devices. Pharmaceutical aseptic filling also needs this class. Aerospace uses iso class 5 for NASA satellites and parts.

Semiconductor cleanroom (photolithography)

Medical device cleanroom (final clean and packaging)

Pharmaceutical cleanroom (aseptic filling)

Aerospace (satellite assembly, component manufacturing)

Hard disk making and repair

R&D cleanroom (Universities and National Labs)

Pharmaceutical compounding

Industry | Application Description |

|---|---|

Pharmaceutical | Aseptic filling |

Biotechnology | Bioprocessing applications |

Semiconductor Manufacturing | Photolithography and other processes |

Medical Device Production | Final clean and packaging |

Aerospace | Satellite assembly, component manufacturing |

Iso class 5 must keep particles below 100,000 per cubic meter at 0.1 microns. You need HEPA or ULPA filters. Air flow must be controlled carefully. You follow strict cleaning and gowning rules.

Advanced filtration and careful control protect sensitive products in iso class 5.

Iso class 6 is for clean spaces for medical parts that go inside the body. Catheters and stents need this class. Iso class 6 has tighter limits than iso class 7. You must keep particles below 1,000,000 per cubic meter at 0.1 microns. Strong air filters and regular cleaning help you meet these rules.

Cleanroom Class | Maximum Allowable Particle Concentration | Applications |

|---|---|---|

ISO Class 6 | More stringent requirements (Class 1,000) | Parts entering the patient's body (e.g., catheters, stents) |

ISO Class 7 | Less stringent requirements (Class 10,000) | Products in direct contact with patients but not invasive (e.g., surgical gowns, wound dressings) |

You check particle levels often in iso class 6. This keeps medical products safe for patients.

You use ISO Class 7 cleanrooms when you need clean air. These rooms do not have the strict rules of iso class 5. ISO Class 7 lets in up to 352,000 particles per cubic meter at 0.5 micrometers. You see these rooms in medical device factories and electronics assembly. Pharmaceutical packaging also uses ISO Class 7. You must wear gowns and use air showers. You need HEPA filters and clean the room often.

ISO Class 7 cleanrooms help support iso 5 cleanroom spaces.

You use these rooms for packaging, inspection, and storage.

You must check particle levels and keep surfaces clean.

ISO Class 7 gives you a good mix of cleanliness and cost. You protect your products without using extreme steps like iso 1 cleanroom or iso class 5.

You use ISO Class 8 cleanrooms for many jobs. These rooms let in up to 3,520,000 particles per cubic meter at 0.5 micrometers. You see ISO Class 8 in pharmaceutical work and biotechnology. Electronics, aerospace, food processing, and medical device factories also use this class.

Here is a table that shows how many particles are allowed and where ISO Class 8 is used:

Allowable Particle Count | Common Applications |

|---|---|

3,520,000 particles/m³ (≥ 0.5 µm) | Pharmaceutical and Biotechnology |

Electronics | |

Aerospace | |

Food Processing | |

Medical |

You use ISO Class 8 cleanrooms for:

Medical device factories

Pharmaceutical manufacturing and compounding

Semiconductor factories

Electronics factories

You must keep these rooms clean. You do not need strict controls like iso class 5. You wear basic gowns and clean the room. You use HEPA filters to keep the air clean.

ISO Class 8 cleanrooms help you follow cleanliness rules without spending too much money. You pick this class for products and jobs that are less sensitive.

You use ISO Class 9 cleanrooms when you only need a little control over particles. These rooms let in up to 35,200,000 particles per cubic meter at 0.5 micrometers. ISO Class 9 is almost like a regular office. You use these rooms for changing clothes or as buffer zones before entering cleaner rooms.

ISO Class 9 cleanrooms have the least control.

You allow up to 35,200,000 particles bigger than 0.5 µm.

You allow up to 8,320,000 particles bigger than 1 µm.

You allow up to 293,000 particles bigger than 5 µm.

You use these rooms for getting ready to enter iso class 5 or iso 5 cleanroom spaces.

ISO Class 9 cleanrooms help you separate clean areas from normal workspaces. You do not need special filters or strict cleaning.

You see that iso 1 cleanroom to ISO Class 9 covers every need. You pick the right class for your products and jobs. This helps you protect your work and follow industry rules.

An iso 1 cleanroom is the cleanest type. It uses strong air filters to keep air very clean. HEPA filters take out almost all particles. The air changes 500 to 750 times each hour. Most of the ceiling has Fan Filter Modules. This is more than other cleanrooms. These things help keep particle counts below 12 for small sizes.

You must follow strict rules in an iso 1 cleanroom. Workers wear special clothes and clean surfaces a lot. Air quality is checked all the time. People go through air showers to remove dust. Special tools count particles and check for contamination. No food, drinks, or extra items are allowed inside.

Iso 1 cleanrooms are used for jobs needing very clean air. Making semiconductors needs this level of control. Nanotechnology research also uses these rooms. Advanced biotechnology labs need iso 1 cleanrooms too. Even one particle can ruin products in these places.

An ISO 5 cleanroom is clean but easier to use. It uses HEPA or ULPA filters to keep air clean. Airflow is controlled and surfaces are kept clean. Workers wear gowns and gloves to stop contamination.

You must clean carefully in an ISO 5 cleanroom. Particle levels are checked often. Workers use air showers and change clothes before entering. Equipment and tools are kept clean. Staff must learn and follow all rules.

ISO 5 cleanrooms are used for many important jobs. Here are some examples:

Sterile drugs and medical devices are made in these rooms.

Sensitive products are processed without germs.

Electronics are put together where tiny particles matter.

Medical devices are packaged and prepared for use.

ISO 7 cleanrooms are used for big factories. These rooms limit particles to 352,000 per cubic meter. Air changes 60 to 90 times each hour. HEPA filters catch almost all big particles. These things help keep products safe from contamination.

ISO 7 cleanrooms are used for packaging medicine and making electronics. These rooms help support cleaner spaces like iso 6 cleanroom areas. Products are stored and checked in ISO 7 cleanrooms. Medical devices are made and prepared in these rooms.

Tip: Always pick the cleanroom class that fits your product. This helps keep your work safe and follow rules.

Cleanroom Class | Air Changes per Hour | Particle Limit (≥0.5 µm/m³) | Common Use |

|---|---|---|---|

ISO 1 | 500-750 | <12 | Semiconductor, nanotech |

ISO 5 | 240-360 | 3,520 | Pharma, electronics |

ISO 7 | 60-90 | 352,000 | Packaging, assembly |

ISO 6 | 180-240 | 35,200 | Medical parts, support |

Iso 6 cleanroom and iso class 6 spaces help both cleaner and less clean areas. Iso 6 cleanroom is used for medical parts that go inside the body. Iso class 6 is for jobs needing more control than ISO 7 but less than ISO 5.

There is a big difference between ISO Class 1 and ISO Class 9 cleanrooms. ISO Class 1 lets in only 10 particles for each cubic meter. ISO Class 9 allows up to 1 billion particles in the same space. ISO Class 1 is much cleaner than ISO Class 9. It is one hundred million times cleaner. You need to pick the right class for your work. Air quality changes a lot between these classes.

Classification | Maximum Particles/m³ |

|---|---|

ISO 1 | 10 |

ISO 9 | 1.0 x 10^9 |

It is important to know about particle size thresholds. Cleanrooms set rules for different particle sizes, like 0.1 micrometers and 0.5 micrometers. Small particles can cause problems in sensitive jobs. ISO Class 1 controls very tiny particles. ISO Class 9 allows bigger particles and more of them.

You need to check how many particles are allowed in each cleanroom class. Lower classes, like ISO Class 1, keep particle counts very low. Higher classes, like ISO Class 9, let in more particles. This helps you pick the best cleanroom for your products.

Cleanliness means counting how many particles are in the air. ISO classes have strict limits for this. ISO Class 1 is the cleanest. ISO Class 9 is the least clean. These limits help keep products safe and follow rules.

There are many ways to measure cleanliness in cleanrooms. You check how fast air moves and which way it goes. You test HEPA filters with smoke. You measure pressure between rooms. You watch temperature and humidity. You see how fast the room gets clean after a mess. You use smoke to look at airflow patterns.

Measurement Method | Description |

|---|---|

Airflow Velocity | Checks how fast air moves in the cleanroom. |

Airflow Direction | Makes sure air flows the right way. |

HEPA Filter Integrity | Uses smoke to test filter effectiveness. |

Differential Pressure | Measures pressure differences to stop contamination. |

Temperature and Humidity | Keeps conditions right for cleanroom work. |

Recovery Rates | Checks how fast the room gets clean again. |

Airflow Visualization | Uses smoke to see airflow patterns. |

You also use HEPA or ULPA filters. You control how often air changes. You follow strict rules for cleaning and wearing special clothes.

Picking the right ISO class lowers contamination risks. Cleanroom classes set strict limits for particles. Cleaner rooms protect sensitive products and help you follow rules. Good control keeps your work safe and stops damage.

Cleanroom Classification | Maximum Allowable Particle Concentration | Impact on Contamination Control |

|---|---|---|

ISO Class 1 | 10 particles/m³ (≥0.1 µm) | Extremely low contamination risk |

ISO Class 5 | 3,520 particles/m³ (≥0.5 µm) | Low contamination risk |

ISO Class 7 | 352,000 particles/m³ (≥0.5 µm) | Moderate contamination risk |

Cleanroom classes help keep products safe.

Cleaner rooms mean less contamination.

Good control saves time and money.

ISO Classes 1 to 3 are used for jobs needing very clean air. Semiconductor factories, nanotechnology labs, and advanced biotech labs need these classes. Even one particle can ruin products in these places.

ISO Classes 4 to 6 are used in healthcare and microelectronics. ISO Class 6 helps make sterile medicine and surgical tools. These classes are also used for sensitive equipment in semiconductor factories.

ISO 7 cleanrooms are used for packaging, checking, and storing products. Pharmaceutical factories use ISO 7 cleanrooms as buffer zones. Electronics and semiconductor factories use ISO 7 cleanrooms to lower particle problems. Aerospace, optics, biotechnology, and medical device factories use ISO 7 cleanrooms to meet standards. Cell and gene therapy labs need ISO 7 cleanrooms for clean work. Sterile pharmacies and electronics factories use ISO 7 cleanrooms for safety. Microprocessor and sensor factories also use ISO 7 cleanrooms.

You need to match the cleanroom class to your job. This keeps products safe and helps you follow important rules.

When you choose a cleanroom, you must look at your industry’s needs. Each field has its own standards for air cleanliness and contamination control.

You work with products that must stay sterile. Even a small amount of contamination can ruin a batch. You often need cleanrooms with strict controls. Many pharmaceutical jobs use ISO Class 5 or ISO Class 7, but some packaging areas use iso 8 cleanroom spaces. You must follow rules for air quality, cleaning, and staff training.

You build tiny parts that dust can destroy. Semiconductor factories often need ISO Class 3 or ISO Class 5. For less sensitive steps, you might use iso 8 cleanroom areas. You must keep particles low to protect chips and circuits.

You make parts for planes and satellites. These parts must work in tough places. You use cleanrooms to stop dust and other particles from causing problems. Some assembly uses ISO Class 5, but you may use iso 8 cleanroom for storage or less critical work.

You make tools and devices for doctors and patients. These products must stay clean to keep people safe. You use ISO Class 7 for assembly and iso 8 cleanroom for packaging. You must check air quality and follow cleaning rules.

You want to keep food safe from germs and dust. Some jobs use iso 8 cleanroom to pack or process food. You do not always need a cleanroom, but when you do, you must follow rules for air and surface cleanliness.

Here is a table that shows what you must consider:

Requirement | Description |

|---|---|

Cleanliness Requirements | Each industry needs a different level of cleanliness. For example, semiconductors need ISO Class 3, while medical device packaging uses iso 8 cleanroom. |

Regulatory Compliance | Some jobs have strict rules about which cleanroom class you must use. |

Process Sensitivity | If your work is sensitive to dust or germs, you need a cleaner room. |

Cost Considerations | Cleaner rooms cost more to build and run. You must balance your needs with your budget. |

You must know how sensitive your products are to dust and germs. This helps you pick the right cleanroom class.

Some products get damaged by even tiny particles. If your product is very sensitive, you need a cleaner room. If it can handle more dust, you can use iso 8 cleanroom. You must check what particle sizes can hurt your product.

Products that need high protection use lower ISO classes.

Less sensitive products can use iso 8 cleanroom.

If germs can ruin your product, you need to control microbes. You must use cleanrooms with rules for cleaning and air flow. Iso 8 cleanroom can help for packaging, but you may need stricter classes for making sterile items.

Heat, humidity, and static can also affect your products. You must control these in your cleanroom. Iso 8 cleanroom helps with basic control, but you may need more for sensitive work.

The more sensitive your product, the stricter your cleanroom must be.

You must match the cleanroom class to your product’s needs.

You must follow rules set by your industry and government. These rules tell you which cleanroom class to use.

You must use ISO 14644-1 to check air quality. This standard tells you how many particles are allowed in each class, including iso class 8.

If you make drugs or medical devices, you must follow FDA and GMP rules. These rules cover how you design your cleanroom, train your staff, and check for contamination. You must use HEPA filters and test your air often.

Some industries have extra rules. For example, the EU has GMP Annex 1, which adds more checks for microbes and cleaning steps. You must know all the rules for your field.

Standard | Description |

|---|---|

ISO 14644-1 | Sets air cleanliness levels for cleanrooms, including iso class 8. |

EU GMP Annex 1 | Adds rules for microbes and cleaning in cleanrooms. |

FDA Guidelines | Focus on design, staff training, and air monitoring to stop contamination in drug products. |

Tip: Always check your industry’s rules before you pick a cleanroom class. This helps you stay safe and follow the law.

You should start by looking at what your industry requires. Each industry has different standards for cleanrooms. For example, making medicine needs stricter air quality than packaging food. Think about what your product needs to stay safe. Some products get damaged by tiny particles. Others can handle more dust. If your work involves sensitive electronics, you may need a cleaner room than if you package food. Always match the cleanroom class to your product and industry.

You must check the rules that apply to your work. Many industries follow strict regulations like FDA, GMP, or ISO 14644-1. These rules tell you what cleanroom class you need. For example, drug manufacturing often requires ISO Class 5 or ISO Class 7. Some jobs, like basic storage, may only need iso class 9. Review all the regulations before you start building or upgrading your cleanroom.

You need to compare the different cleanroom classes. Look at how many particles each class allows. Lower classes, like ISO Class 1, keep the air very clean. Higher classes, like iso class 9, allow more particles. Make a list of your options. Think about what level of cleanliness your product needs. Use tables or charts to help you see the differences. This makes it easier to choose the right class.

Cleanroom Class | Particle Limit (≥0.5 µm/m³) | Typical Use |

|---|---|---|

ISO 1 | <12 | Semiconductor, nanotech |

ISO 5 | 3,520 | Pharma, electronics |

ISO 7 | 352,000 | Packaging, assembly |

ISO 9 | 35,200,000 | Storage, changing areas |

You should think about how much money you can spend. Cleaner rooms cost more to build and run. You need special filters, more air changes, and strict cleaning. Higher classes, like ISO 1, need more care than iso class 9. Make a budget for building, equipment, and ongoing cleaning. Also, plan for regular checks and repairs. This helps you avoid surprises later.

Tip: Cleaner rooms protect your products, but they also cost more. Balance your needs with your budget.

You can get help from cleanroom experts. These professionals know the rules and best practices. They can help you design your space, pick the right materials, and set up your HVAC system. Experts can also help you review your floor plan, entry points, and workflow. They make sure your cleanroom meets all standards and works well for your team.

Checklist for Selecting a Cleanroom Class:

Review all regulations (FDA, GMP, ISO 14644-1).

Create a floor plan with entry and exit points.

Choose the right flooring and wall materials.

Design the HVAC system for your cleanroom class.

Plan window placements for comfort and visibility.

Make sure you have all needed utilities and services.

Note: Following a checklist helps you avoid mistakes and keeps your products safe.

You must think about building costs for a cleanroom. The price changes based on the class you pick. Cleaner rooms cost more because they need better filters. They also need tighter controls. In Ontario, a cleanroom can cost $300 per square foot. Some are as cheap as $100 per square foot. Others can cost up to $1,000 per square foot. ISO 8 or ISO 7 cleanrooms cost between $250 and $1,500 per square foot. These prices show why you must pick the right class for your needs.

Lower ISO classes are more expensive to build.

ISO 8 and ISO 7 cleanrooms have a big price range.

Better filters and air systems make costs go up.

You must plan for costs after the room is built. Cleaner rooms use more energy and need filter changes often. You pay for training, cleaning, and testing. ISO 1 and ISO 5 cleanrooms use more power because they move air faster. ISO 8 cleanrooms cost less to run but still must meet rules.

You should think about if cleaner rooms are worth the cost. Cleaner rooms protect products and help you follow rules. If your products need strict rules, spending more is smart. If your work can handle more dust, you save money with a higher ISO class.

Tip: Always check if the cost of your cleanroom matches the value it brings.

You need a plan for long-term costs. Save money for repairs, upgrades, and tests. Cleanroom rules can change, so you may need updates. Set aside money for new filters and tools. Good planning helps you avoid problems and keeps your room up to standard.

You must clean your cleanroom often. Use the right cleaning products and follow all steps. Workers wear special clothes to keep dust out. Cleaning helps you meet rules and keeps products safe.

You need to test air and surfaces often. Use particle counters and check filters. Write down results to show you follow the rules. Testing helps you find problems early.

Cleaner rooms are harder to keep clean. You must clean more and test air more often. Less clean rooms need fewer checks. Each class has its own cleaning and testing rules.

You should do regular checks to stop problems. Change filters before they break. Teach workers to spot issues. Plan inspections often. These steps help you follow rules and keep your room working well.

You may need to change your cleanroom class. Check if your products or rules have changed. Look at your process to see if you need stricter controls.

To upgrade, add better filters and fix airflow. Teach workers new rules. Update cleaning steps and test more often.

Downgrading saves money but can raise contamination risk. Make sure your products can handle less strict rules. Think about all effects before you decide.

Changing your cleanroom class means new rules. You must update records and follow new standards. Check with rule makers before you change anything.

Changing your cleanroom class can slow down your work. Plan for extra costs and time off. Good planning helps you avoid trouble and keeps your room up to standard.

You see big differences between ISO cleanroom classes. ISO 1 keeps air almost free of particles. ISO 9 allows many more. You must pick the right class for your products and jobs. Use the tables and tips in this guide to help you decide.

Match your cleanroom to your needs.

Protect your products and follow rules.

Understanding ISO cleanroom classifications helps you build safer spaces and succeed in your industry.

Iso cleanroom classifications set rules for air particles. These rules help keep products safe from contamination. You follow them to meet industry needs and protect important work.

Each iso class allows a different amount of particles. Lower classes, like iso class 2, have cleaner air. Higher classes let in more particles. You pick the class that fits your product and process.

Clean room standards help stop contamination. You use these rules to meet laws and industry rules. Following standards keeps products safe and helps you follow cleanroom rules.

Iso 1 cleanroom has the strictest particle limits. You need advanced filters and must check air quality all the time. Workers wear special clothes and clean carefully to keep the room clean.

Iso class 2 cleanrooms are used for electronics and optics. These rooms need strong filters and regular particle checks. You must test air often to meet iso rules.

You clean surfaces often with special cleaning products. Workers wear gowns and gloves to stop contamination. You test air and change filters regularly to keep the room clean.

Choosing the wrong class can cause contamination. Your products may not meet clean room rules. You could have legal trouble or lose customer trust. Always pick the right class and follow iso cleanroom rules.

Iso classifications help you pick the best cleanroom for your work. Different industries use different classes, like pharmaceuticals, electronics, and aerospace. You follow these rules to protect products and meet clean room standards.

Tip: Always check your industry’s needs before you choose a cleanroom class. This helps you save money and keeps your products safe.