- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-12 Origin: Site

You see cleanroom classes according to ISO 14644-1 and GMP when you need to control contamination. Cleanroom classification sets limits for particles and germs in places like drug labs or electronics factories. The ISO system uses cleanroom classes according to ISO 14644-1 and GMP, ranging from 1 to 9, focusing on how clean the air is. GMP grades go from A to D, emphasizing total quality and control of germs. Cleanroom classes according to ISO 14644-1 and GMP are crucial for good manufacturing practices today. ISO cleanroom standards are utilized across many industries, while GMP is essential for drug manufacturing.

The drug industry constitutes almost half of the cleanroom market.

Healthcare is driving rapid growth in cleanrooms.

Germany and Switzerland enforce strict cleanroom regulations.

Aspect | ISO 14644-1 | GMP (Good Manufacturing Practice) |

|---|---|---|

Scope | Global standard for many industries | Rules mainly for making drugs |

Regulatory Status | Voluntary, best practices | Required, checked by regulators |

Focus Areas | Air cleanliness and monitoring particles | Total quality and limits for germs |

Cleanroom Classification | Classes 1-9 based on particles | Grades A-D based on cleanliness |

Cleanroom classes in ISO 14644-1 go from 1 to 9. These numbers show how clean the air is. GMP grades go from A to D. GMP grades focus on quality and germ control.

ISO Class 1 is the cleanest. It is used for very sensitive products. ISO Class 9 has the most particles. It is used in places that are not as strict.

GMP Grade A is needed for filling sterile drugs. It needs very strict rules. Grade D is for jobs that are not as critical. It allows more particles in the air.

Companies like drug makers and electronics use cleanroom rules. These rules help keep products safe. They also help follow laws.

It is important to check air quality often. Use particle counters and tests for germs. This helps keep the cleanroom up to standard.

Pick the right cleanroom class for your product. If your product is sensitive, use a lower class number. Lower numbers mean stricter rules for keeping things clean.

Air must change many times each hour. Good filters like HEPA or ULPA are needed. These help keep the cleanroom clean.

Write down all cleaning and checking steps. This helps you follow ISO and GMP rules. It also helps when you have audits or inspections.

Image Source: unsplash

When you work in a cleanroom, you must check the air. Cleanroom classification helps you count tiny particles and germs. These standards keep products safe and stop contamination. ISO 14644 and GMP set rules for how clean a space needs to be. ISO 14644 uses classes from 1 to 9. GMP uses grades from A to D. You pick the right cleanroom class based on what you make, like medicine or electronics.

Class/Grade | Description | |

|---|---|---|

ISO 14644-1 | This is the cleanest air level. It has the fewest particles allowed. | |

ISO 14644-1 | ISO Class 9 | This is the least clean air level. It has the most particles allowed. |

EU GMP Annex 1 | This matches ISO Class 5. It is needed where products are exposed. | |

EU GMP Annex 1 | Grade D | This is close to ISO Class 8. It is used for less important steps in making products. |

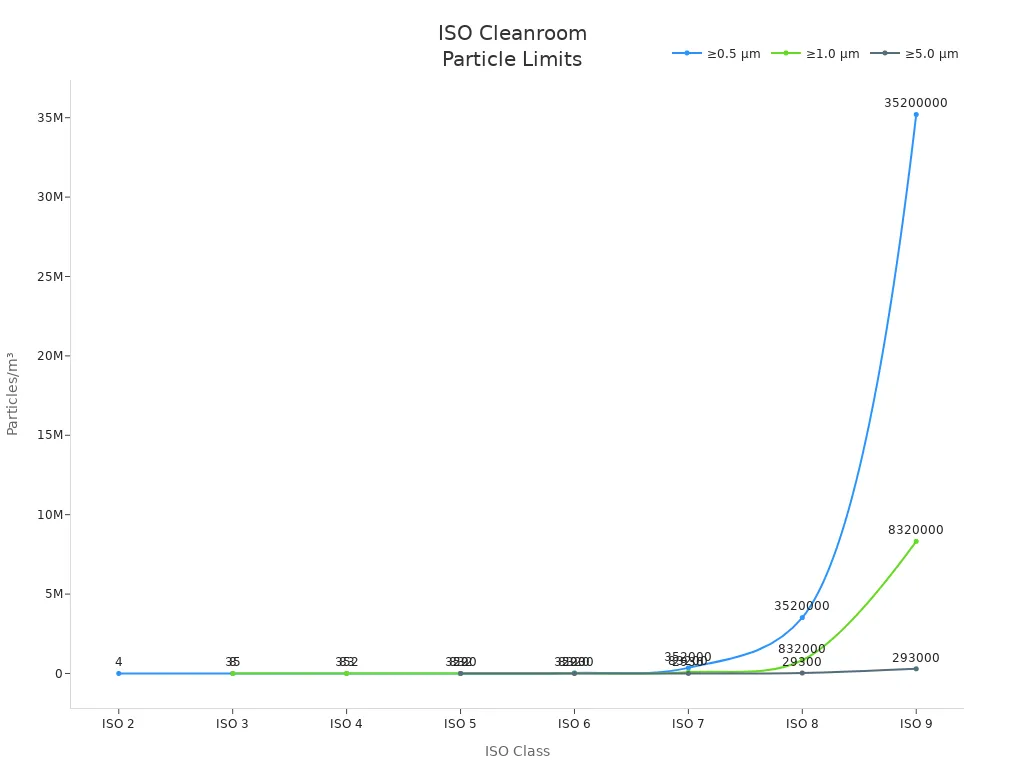

ISO 14644 cleanroom classes count particles in the air. These standards help you know how clean your workspace should be. ISO class 1 is the cleanest. ISO class 9 is the least clean. ISO class 5 is used in places like chip factories. Even a tiny particle can ruin a microchip. ISO class 7 is common in making medicine. You need some control there.

ISO Class | ≥0.1 µm | ≥0.2 µm | ≥0.3 µm | ≥0.5 µm | ≥1.0 µm | ≥5.0 µm |

|---|---|---|---|---|---|---|

ISO 1 | 10 | 2 | — | — | — | — |

ISO 2 | 100 | 24 | 10 | 4 | — | — |

ISO 3 | 1,000 | 237 | 102 | 35 | 8 | — |

ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | — |

ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 |

ISO 6 | — | — | — | 35,200 | 8,320 | 293 |

ISO 7 | — | — | — | 352,000 | 83,200 | 2,930 |

ISO 8 | — | — | — | 3,520,000 | 832,000 | 29,300 |

ISO 9 | — | — | — | 35,200,000 | 8,320,000 | 293,000 |

Many industries use ISO 14644 cleanroom classes. Medical device cleanrooms use ISO class 7 or 8. Labs for vaccines use ISO class 5. Aerospace companies use ISO class 7 or 8 for satellites.

GMP cleanroom grades control both particles and germs. Grade A is the highest level. You need grade A for filling sterile drugs. Any contamination can hurt patients. Grade D is the lowest. You use grade D for less important steps, like handling raw materials. GMP cleanroom grades help you follow strict rules in drug making.

Cleanroom Class | Particle Limits (≥ 0.5 µm) | Particle Limits (≥ 5 µm) | Air Sample (CFU/m³) | Settle Plates (CFU/4 hours) | Contact Plates (CFU/plate) |

|---|---|---|---|---|---|

A | 3,520 | Not specified | No growth | 10 | 5 |

B | 3,520 | Not specified | 10 | 50 | 5 |

C | 352,000 | 2,930 | 100 | 50 | 25 |

D | 3,520,000 | 29,300 | 200 | 100 | 50 |

Grade A is used for injectable drugs. Grade D is for less important areas. Medical device cleanrooms may use grade B or C. It depends on the risk. GMP cleanroom grades make sure you follow safety rules and protect patients.

When you look at cleanroom classification systems, you notice some big differences between iso 14644 and gmp. Both systems help stop contamination, but they focus on different things. Iso 14644 cleanroom classifications set strict rules for particles in the air. These standards are used in many places, like electronics, aerospace, and nanotechnology. Gmp cleanroom grades pay attention to both particles and germs. You mostly see these grades in drug making and healthcare.

Iso 14644 cleanroom classification uses numbers from 1 to 9. Iso class 1 is the cleanest. Iso class 9 is the least clean. Gmp grades use letters from A to D. Grade A is the cleanest level. Grade D is the least clean. You pick the right cleanroom based on what you make and how you make it.

Iso 14644 standards help you check and control particles. Gmp guidelines make you control germs and write down every step. You must follow strict rules to keep products safe.

Here is a table that shows the main differences in contamination control:

Classification | Maximum Particles per Cubic Meter (≥0.5 µm) | Typical Applications |

|---|---|---|

ISO Class 1 | 10 | Advanced nanotechnology |

ISO Class 2 | 100 | Semiconductor fabs |

ISO Class 3 | 1,000 | Microelectronics, aerospace |

ISO Class 4 | 10,000 | High-end optics |

ISO Class 5 | 100,000 | Pharmaceutical filling (GMP Grade A) |

ISO Class 6 | 1,000,000 | Aseptic processing (GMP Grade B) |

ISO Class 7 | 352,000,000 | Medical device manufacturing |

ISO Class 8 | 3,520,000,000 | General pharmaceutical environments |

ISO Class 9 | 35,200,000,000 | Clean industrial spaces |

Gmp cleanroom grades set rules for both particles and germs. Grade A needs the most control. You use grade A for sterile products. Grade B is for aseptic processing. Grade C and D allow less control and are used for less sensitive jobs.

Iso 14644 cleanroom classification looks at air cleanliness. You count particles and check the air. Gmp cleanroom grades add more steps. You must watch for germs, write down what you do, and follow strict rules for safety. Iso standards work for many industries. Gmp standards are very important for drug making.

You need to know these differences when you choose a cleanroom. Iso 14644 cleanroom classifications help you control particles. Gmp cleanroom grades help you control both particles and germs. You must pick the right system for your product and process. Cleanroom classification keeps your workspace safe and your products high quality.

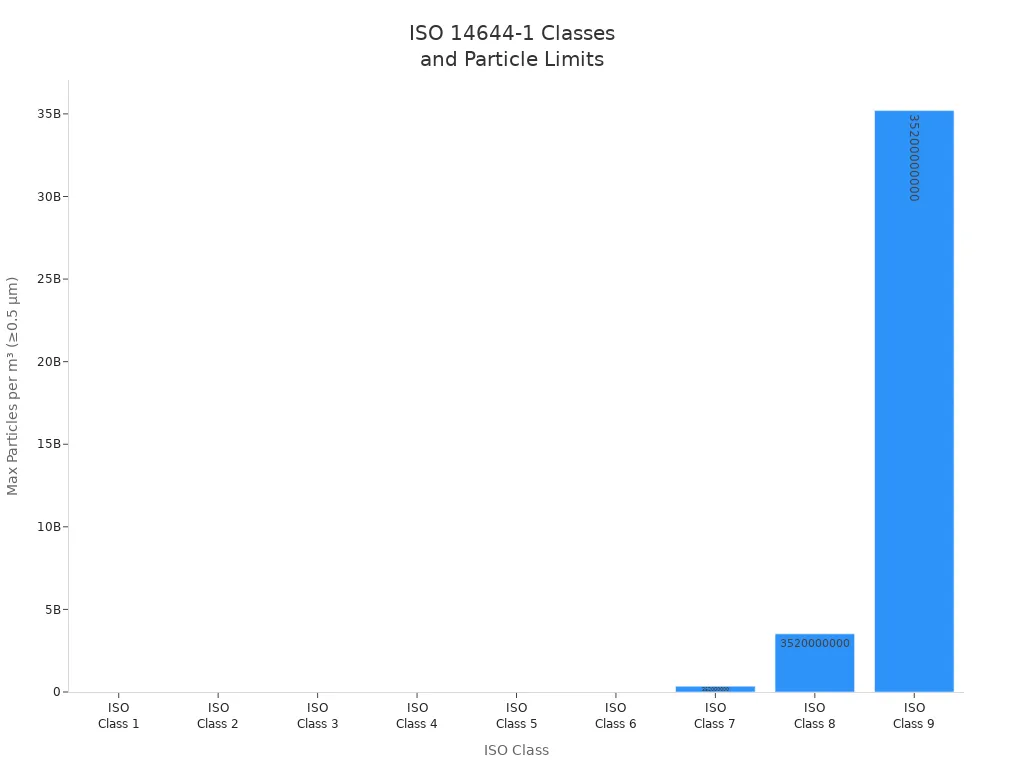

When you look at iso 14644, you see nine different cleanroom classes. Each class sets a limit for how many tiny particles can float in the air. You use these classes to decide how clean your workspace needs to be. The lower the class number, the cleaner the air. Class 1 is the cleanest. Class 9 is the least clean. You pick a class based on what you make and how sensitive your products are to contamination.

You can see the particle limits for each iso 14644 class in the table below. This table shows how many particles of certain sizes are allowed in each cleanroom. These numbers help you understand how strict the air quality rules are for each class.

ISO Class | Particles per cubic meter (0.3 µm) | Particles per cubic meter (0.5 µm) |

|---|---|---|

1 | 12 | 0 |

2 | 102 | 2 |

3 | 1,020 | 10 |

4 | 10,200 | 102 |

5 | 102,000 | 1,020 |

6 | 1,020,000 | 10,200 |

7 | 10,200,000 | 102,000 |

8 | 35,000,000 | 350,000 |

9 | 35,000,000 | 35,000,000 |

Tip: You should always check the particle size that matters most for your process. Some products need stricter control for smaller particles.

You find iso 14644 cleanroom classes in many industries. If you work in electronics, you might need class 5 or even class 3. These classes protect microchips from dust. In the pharmaceutical industry, you often use class 5 or class 7. These classes help you meet gmp rules for drug safety. Aerospace companies use class 7 or class 8 to keep satellites and parts clean. Medical device makers often choose class 7 or class 8 for assembly areas.

You decide which iso 14644 class you need by looking at your product and process. Start by thinking about how sensitive your product is to particles. If a single speck can ruin your product, you need a lower class. You also look at gmp requirements if you make drugs or medical devices. Cleanroom standards help you match your workspace to your needs.

You also need to know about cleanroom states:

As-built: The cleanroom is empty, with only filters running. This is the cleanest state.

At Rest: Equipment and products are inside, but no one is working yet. This state is less clean than as-built.

Operational: People are working inside. This is usually the dirtiest state.

You test your cleanroom in all these states to make sure it meets iso 14644 rules. You count particles in the air and compare the results to the class limits.

Here is a quick look at the particle limits for iso 14644 cleanroom classifications:

ISO Class | 0.3 µm (particles/m³) | 0.5 µm (particles/m³) |

|---|---|---|

1 | 12 | 0 |

2 | 102 | 2 |

3 | 1,020 | 10 |

4 | 10,200 | 102 |

5 | 102,000 | 1,020 |

6 | 1,020,000 | 10,200 |

7 | 10,200,000 | 102,000 |

8 | 35,000,000 | 350,000 |

9 | 35,000,000 | 35,000,000 |

You use these numbers to check if your cleanroom meets the right iso 14644 class. Cleanroom standards like iso 14644 and gmp help you keep your workspace safe and your products high quality.

GMP cleanroom standards have four main grades. These are Grade A, Grade B, Grade C, and Grade D. Each grade means a different level of cleanliness. Grade A gives the most protection. You use it for risky jobs like aseptic filling. Grade B helps keep Grade A areas clean. Grade C and Grade D are for less important steps.

Grade A is for very sensitive work. Laminar airflow workstations help keep air clean.

Grade B is the background for Grade A. You need it for preparing and filling drugs.

Grade C is for less important jobs, like making solutions.

Grade D is for general drug production areas.

GMP cleanroom grades match ISO classes. Grade A matches ISO 5. Grade B fits ISO 5 to ISO 7. Grade C matches ISO 7. Grade D matches ISO 8. You must follow these rules to meet EU GMP Annex 1 and FDA laws.

You need to know how your cleanroom works in two states. GMP and ISO 14644 talk about these states:

At Rest: Equipment is in the cleanroom. No one is working. You check particle levels to see how clean it is.

In Operation: People are working inside. You check particles and germs during production.

You must test your cleanroom in both states. Grade A and Grade B need strict control, especially when people work inside. Grade C and Grade D allow more particles and germs, but you still need to check them.

Tip: Always check your cleanroom during real work. Particle counts can go up fast when people move.

GMP cleanroom rules set clear particle limits for each grade. You must count particles in the air and keep them below the set numbers. Grade A and Grade B have the lowest limits. Grade C and Grade D allow more particles.

Grade | Airborne Particulate Classification | ISO Class Equivalent | Particle Limit (≥0.5 µm) |

|---|---|---|---|

A | ISO 5 / Class 100 | ISO 5 | 3,520 |

B | ISO 5–7 / Class 100–10,000 | ISO 5–7 | 3,520–352,000 |

C | ISO 7 / Class 10,000 | ISO 7 | 352,000 |

D | ISO 8 / Class 100,000 | ISO 8 | 3,520,000 |

You must keep your cleanroom within these limits. This helps you meet good manufacturing practices and pass checks under EU GMP Annex 1 and FDA laws.

Here is a table with the main rules for each GMP cleanroom grade. You can use this table when you set up your workspace.

Grade | ISO Class | Typical Use | Particle Limit (≥0.5 µm) | Operational State Requirements |

|---|---|---|---|---|

A | ISO 5 | High-risk jobs (aseptic filling) | 3,520 | Strict control at rest and in operation |

B | ISO 5-7 | Background for Grade A, drug preparation | 3,520–352,000 | High control, especially in operation |

C | ISO 7 | Less important jobs | 352,000 | Moderate control at rest and in operation |

D | ISO 8 | General drug production | 3,520,000 | Basic control, focus on at rest |

Grade A and Grade B need the most control. Grade C and Grade D allow more particles, but you must still follow the rules.

You use GMP cleanroom grades in many drug and biotech jobs. Here are some common examples:

Cleanroom Grade | Cleanliness Level | Typical Applications |

|---|---|---|

Grade A | ISO 5 | Risky jobs like aseptic filling |

Grade B | ISO 5-7 | Drug preparation and filling |

Grade C | ISO 7 | Less important jobs |

Grade D | ISO 8 | General drug production areas |

You use Grade A for filling sterile drugs. Grade B helps keep Grade A areas clean. Grade C is for making solutions. Grade D is for handling raw materials or basic jobs.

Note: You must pick the right cleanroom grade for each step. This helps you follow good manufacturing practices and keep products safe.

You see GMP cleanroom grades in vaccine labs, biotech factories, and medical device plants. You must follow ISO 14644, EU GMP Annex 1, and FDA rules to keep your cleanroom safe and legal.

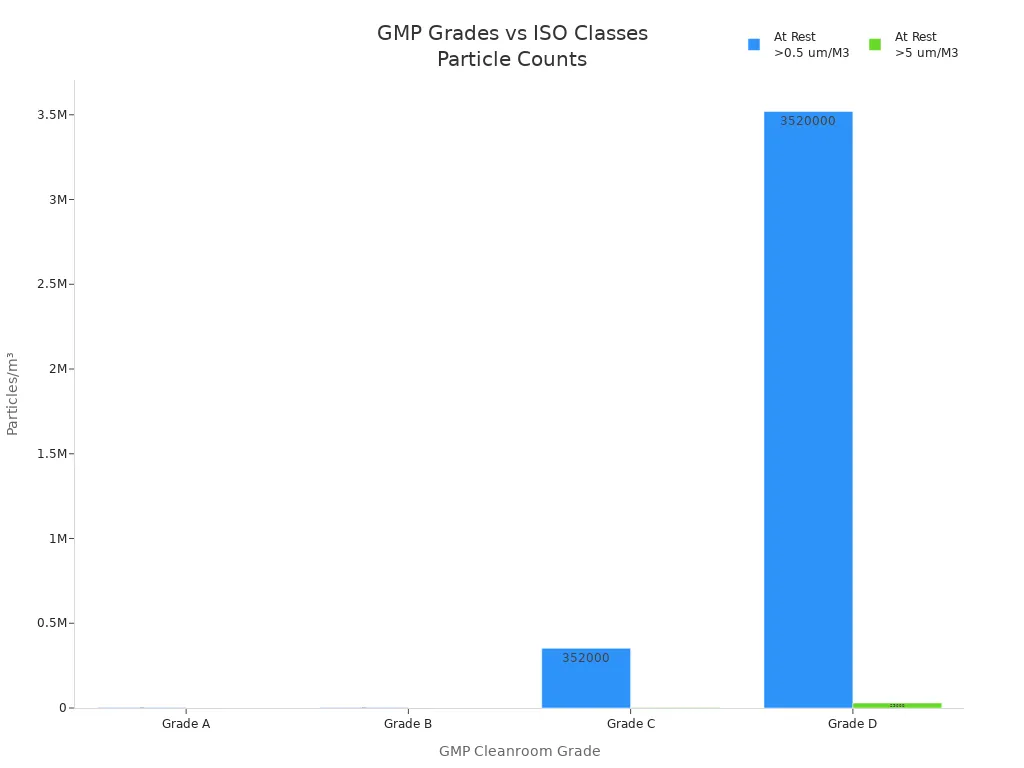

You often need to compare iso 14644 classes with gmp grades when you set up a cleanroom. Both systems help you control contamination, but they use different numbers and letters. You can see how they match in the table below. This table shows the particle limits for each gmp grade and the equivalent iso class. You use these numbers to check if your cleanroom meets the right standards.

GMP Grade | At Rest >0.5 µm/m³ | At Rest >5 µm/m³ | Operational >0.5 µm/m³ | Operational >5 µm/m³ | Equivalent ISO | Equivalent Fed209E |

|---|---|---|---|---|---|---|

A | 3,520 | 20 | 3,520 | 20 | ISO-5 | 100 |

B | 3,520 | 29 | 352,000 | 2,900 | ISO-5/7 | 100/10k |

C | 352,000 | 2,900 | 3,520,000 | 29,000 | ISO-7 | 10k/100k |

D | 3,520,000 | 29,000 | not defined | not defined | ISO-8 | 100k |

You can also see the comparison in the chart below. This chart helps you understand how particle counts change from grade A to grade D and from iso 5 to iso 8.

You need to know how iso 14644 classes and gmp grades match. Grade A matches iso 5. You use this for the cleanest jobs, like filling sterile drugs. Grade B matches iso 5 or iso 7. You use this for background areas that support grade A. Grade C matches iso 7. You use this for less risky steps, such as making solutions. Grade D matches iso 8. You use this for general production or handling raw materials.

Grade A and iso 5 protect the most sensitive products.

Grade B and iso 5/7 keep the environment safe for critical work.

Grade C and iso 7 allow more particles but still need control.

Grade D and iso 8 work for less critical jobs.

You use cleanroom classification to pick the right grade and class for each step in your process. This helps you follow both iso and gmp rules.

Tip: Always check both iso 14644 and gmp standards before you design your cleanroom. This helps you avoid mistakes and keeps your products safe.

When you choose a specific iso class or gmp grade, you change how you build and run your cleanroom. You must think about air filters, monitoring, and cleaning routines. The table below shows what each gmp grade means for your facility.

GMP Grade | Description | Practical Implications |

|---|---|---|

Grade A | High-risk operations like filling and aseptic connections | You need the highest level of cleanliness. You must prevent contamination in critical processes. |

Grade B | Aseptic preparation and filling | You support grade A operations. You keep a controlled environment for sensitive work. |

Grade C | Monitoring in line with quality risk management | You make sure the environment fits less critical jobs. You still maintain quality. |

Grade D | Equivalent to ISO 8 cleanroom at rest | You get a less strict environment. You use this for non-critical jobs, but you still monitor activities. |

You must train your team, set up strict cleaning, and use special filters for higher grades and classes. You also need to monitor particles and germs all the time. If you pick the wrong iso or gmp level, you risk contamination and product failure. You keep your cleanroom safe by matching the right iso 14644 class and gmp grade to your needs.

Image Source: pexels

You need to change the air in cleanrooms often. This helps remove particles and keeps things safe. Each iso 14644 class and gmp grade has its own rules for air changes. If the class number is lower, you need more air changes. Look at the table below to see how many air changes are needed:

ISO Class | Air Changes per Hour |

|---|---|

ISO 1 | 60-100 |

ISO 2 | 60-100 |

ISO 3 | 60-90 |

ISO 4 | 50-90 |

ISO 5 | 40-80 |

ISO 6 | 25-40 |

ISO 7 | 10-15 |

ISO 8 | 1-8 |

ISO 9 | 0-5 |

If you work in a gmp cleanroom, you also check air changes for each grade. For example, ISO-7 cleanrooms may need 60 air changes every hour. ISO-8 cleanrooms might need only 20 air changes.

Filters help keep cleanrooms safe. HEPA filters are used for most iso 14644 classes, especially ISO Class 5 and higher. ULPA filters are needed for the cleanest places, like ISO Classes 1-4. HEPA filters catch 99.97% of particles that are 0.3 microns or bigger. ULPA filters trap even smaller particles, so they are important for strict iso standards.

HEPA filters are good for ISO-3 to ISO-8 cleanrooms.

ULPA filters are needed for ISO-1 to ISO-4 cleanrooms.

You pick the right filter based on your iso class and gmp grade. ULPA filters cost more but give better protection in important areas.

Filters should be placed where they clean the air before it gets to your workspace. Most cleanrooms use filters in the ceiling to push air down. You need to test each filter to make sure it works. You check filter integrity with tests like PAO or DOP. You also measure airflow speed and volume to see if your cleanroom meets iso 14644 and gmp rules.

Tip: Test your filters when you put them in and test them often. This helps you find leaks and keep your cleanroom safe.

You need to check particles in the air to meet iso 14644 and gmp rules. You use special machines called optical particle counters to count non-viable particles. The number of particles in the air helps you know your cleanroom class. You must test when you set up the cleanroom and at regular times.

Microbial monitoring checks for germs in your cleanroom. You use settle plates, air samplers, and contact plates to find bacteria and fungi. GMP cleanroom rules say you must test for germs often, especially in risky areas.

You set alert and action limits to find problems early. Alert levels warn you when particle or germ counts start to go up. Action levels mean you must look into the problem and fix it. GMP rules say you need to set these limits for each cleanroom grade.

Note: Checking often helps you find contamination before it hurts your products.

You must wear special clothes in your cleanroom. The table below shows what you need for each iso class and gmp grade:

Cleanroom Grade | Gowning Requirements |

|---|---|

Grade A/B | Sterile garments, gloves, headgear, face mask, eye coverings, footwear |

Grade C | Hair covered, suit, disinfected shoes or overshoes |

Grade D | Hair covered, protective suit, disinfected shoes or overshoes |

ISO Class 5 and higher need full coveralls, gloves, masks, and hoods. Lower iso classes need less protection.

You must follow steps when you put on cleanroom clothes. Wash your hands, cover your hair, and put on gloves and masks in the right order. Training includes lessons and practice. You need to check your gowning skills every year.

Operators must wash hands before putting on clothes.

Take off clothes in reverse order after use.

You control who goes into your cleanroom to stop contamination. Only trained people can enter high-grade areas. You use airlocks and change rooms to keep clean zones separate from dirty ones. You must check that everyone follows cleanroom rules before going in.

Always check your procedures and train your team to keep your cleanroom safe.

You need to clean your cleanroom a lot to keep it safe. How often you clean depends on your iso 14644 class and gmp grade. High-grade places like Grade B and Grade C need cleaning every day when making products. Lower-grade places, like Grade D, might only need cleaning once a week. Each area uses different ways to clean. Small rooms can be cleaned by hand. Big cleanrooms with strict iso rules may use machines to clean.

Here is a table that shows how cleaning rules fit with cleanroom grades and iso classes:

Cleanroom Grade | ISO Class | FED-STD-209E Class | Description |

|---|---|---|---|

Class 7 | Class 10,000 | Keeps the air very clean while working. | |

Grade C (at rest) | Class 7 | Class 10,000 | Good cleanliness for less risky jobs. |

Grade C (operational) | Class 8 | Class 100,000 | More particles are okay when people are working. |

Grade D | Class 8 | Class 100,000 | Regular cleanroom with lower risk of contamination. |

You should sweep, mop, and wipe all surfaces using approved ways. Always start in the cleanest spot and move to dirtier spots. This stops dirt from spreading.

You have to choose the right cleaning agents for your cleanroom. Iso 14644 and gmp rules say you must use agents that clean well but do not leave anything harmful behind. Liquinox is good for dirt that dissolves in water. CIP-100 is used for dirt made from proteins. You must use the right amount and let it sit for the right time.

The table below shows some common cleaning agents and how to use them:

Cleaning Method | Cleaning Agent | Concentration | Contact Time | Temperature | Additional Notes |

|---|---|---|---|---|---|

Manual Cleaning | 1-2% v/v | 10-15 minutes | 20-25°C | For dirt that dissolves in water | |

Manual Cleaning | CIP-100 | 2-5% v/v | 10-15 minutes | 20-25°C | For protein-based dirt |

Automated Cleaning | N/A | N/A | N/A | 65-80°C | WFI rinses with set programs |

Automated Cleaning | N/A | N/A | N/A | 20-25°C | Detergent cycles with pressure of 30-45 psi |

You must check your cleaning process works. Iso and gmp rules say you have to test surfaces after cleaning. You look for any dirt or germs left behind. If you find a problem, you need to change how you clean or what you use.

Tip: Always use new cleaning solutions and clean tools. This helps you follow iso 14644 and gmp rules.

You must write down every cleaning step in your cleanroom. Iso 14644 and gmp rules say you need to record the date, time, method, and agent used. You also write who did the cleaning and any problems found. Good records help you show your cleanroom meets iso and gmp rules.

You can use a checklist or a cleaning log. Make sure you update your records after each cleaning. Auditors may want to see your records during checks.

Write down every cleaning job.

Record the agent and method used.

Note any problems or changes in how you clean.

Note: Good records help you find patterns and make your cleanroom cleaning better.

You have to think about a few key things when picking a cleanroom class. These things help keep your workspace safe and your products good. Here are the main points you should look at:

Air Filtration Systems: You need strong air filters like HEPA or ULPA. These filters catch tiny particles. They help you meet iso 14644 and gmp rules.

Air Changes Per Hour (ACH): More air changes mean cleaner air. If you want a lower iso class, you need more air changes each hour.

Environmental Control Parameters: You should control temperature, humidity, and airflow. These controls stop contamination and help you follow iso and gmp rules.

Design and Construction Materials: You need smooth surfaces that are easy to clean. Good materials help lower the risk of contamination in your cleanroom.

Intended Use and Process Requirements: The kind of work you do decides the cleanroom class. If you make medicine or microchips, you need stricter iso 14644 classes.

Tip: Always pick a cleanroom class that fits your product’s needs. This helps you avoid problems and keeps your process safe.

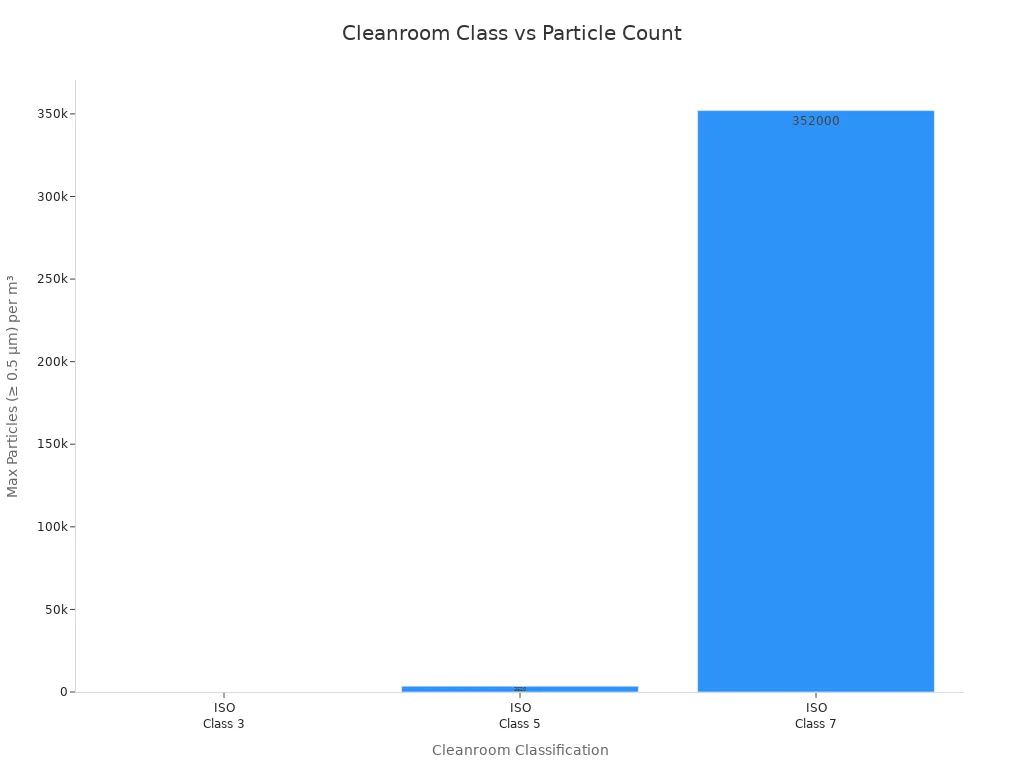

Different industries have their own rules for cleanroom classes. You must follow these rules to meet iso 14644 and gmp standards. For example, drug makers use iso classes from 8 to 5. Medical device makers often need iso class 7 or 5. Electronics factories may use iso class 5 or even class 3 for microchips.

ISO 14644-1 sets limits for particles in the air. Lower class numbers mean stricter control. For example, class III medical devices need iso class 3 to 5 cleanrooms. This keeps products safe from tiny particles.

Maximum Particles (≥ 0.5 µm) per m³ | |

|---|---|

ISO Class 3 | ≤ 35 |

ISO Class 5 | ≤ 3,520 |

ISO Class 7 | ≤ 352,000 |

Drug cleanrooms need iso classes from 8 to 5.

Medical device cleanrooms use iso class 7 to 5.

Both industries must follow FDA and gmp rules.

You need to follow steps to keep your cleanroom at the right iso 14644 class or gmp grade. Every day, you clean surfaces, check airflow, and watch the environment. Each month, you review documents, test filters, and check particle counts. Every quarter, you look at the structure and test pressure. Once a year, you certify the cleanroom, change filters, and check the HVAC system.

Frequency | |

|---|---|

Daily | Surface cleaning, consumables replenishment, airflow checks, environmental monitoring, entry point inspection, equipment operation checks. |

Monthly | Garment evaluation, documentation review, filter testing, particle count analysis. |

Quarterly | Structural assessment, pressure differential validation, equipment qualification. |

Annual | Cleanroom certification, filter replacements, maintenance plan audit, HVAC checkups. |

Note: Regular checks and cleaning help you keep your cleanroom safe and make sure you follow iso 14644 and gmp rules.

You should know how iso 14644 and gmp cleanroom classes are different. Iso 14644 sets rules for how many particles can be in the air. Gmp adds extra rules to control germs. Cleanroom classification helps you keep products safe and follow important laws. Medical device companies use cleanroom rules to make sure products are good and meet standards. Iso standards help you design cleanrooms that protect people and products. When you pick a cleanroom, think about your industry, how risky your product is, and what your process needs. The table below gives easy steps for picking the right cleanroom grade:

Industry | Cleanroom Grade(s) | Key Considerations |

|---|---|---|

Biopharmaceuticals | ISO Class 5-7 | You need to control germs and keep things sterile. Use higher grades if your product touches people directly. |

Semiconductor Manufacturing | ISO Class 1-5 | You must control tiny particles. Use higher grades for making advanced chips. |

Medical Devices | ISO Class 5-8 | You need to follow rules. The grade you pick depends on how risky your product is. |

Tip: Make sure your cleanroom matches your product and process. This keeps your workspace safe and helps you follow iso and gmp rules.

You work in a cleanroom to control particles and germs. Cleanrooms use special air filters and strict rules. These rooms help you keep products safe in industries like medicine and electronics.

ISO 14644-1 classes focus on counting particles in the air. GMP grades add rules for germs and product safety. You choose the system based on your industry and product needs.

Air changes remove particles and keep the room clean. You set the number of air changes based on your cleanroom class or grade. More air changes mean cleaner air.

HEPA filters catch 99.97% of particles at 0.3 microns. ULPA filters trap even smaller particles. You use ULPA filters for the cleanest rooms, like ISO Class 1-4.

You use particle counters and settle plates. These tools help you check for dust and germs. You test the air and surfaces often to keep your cleanroom safe.

You wear special clothes like coveralls, gloves, masks, and shoe covers. The type of gowning depends on your cleanroom grade. Higher grades need more protection.

You clean high-grade cleanrooms every day. Lower-grade rooms may need cleaning once a week. You follow a schedule and use approved cleaning agents.

You must check the product risk and cleanroom requirements. Some products need stricter control. You may need separate rooms or extra cleaning between batches.