- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 188 Author: Site Editor Publish Time: 2025-11-25 Origin: Site

You need a dry room controlled environment if you work with sensitive materials that react to water in the air. Low humidity helps keep batteries, electronics, and medicines safe from harm. The global market size for dry room controlled environments will be about USD 500 million in 2025 and will grow fast. Amber gives you ready-to-use solutions for controlled environments with the newest technology. What Is a Dry Room Controlled Environment? This question is very important now because industries want better safety and quality.

Dry rooms keep humidity under 1%. This protects things like batteries and medicines from water damage.

Strong dehumidification systems are needed to keep humidity low in dry rooms.

Airlocks at doors help stop outside humidity from getting in.

Checking humidity and temperature often is important for safety and quality.

Using good materials like stainless steel helps dry rooms stay sealed and work well.

Many industries, like pharmaceuticals and electronics, use dry rooms to keep products safe.

Smart monitoring systems give real-time data. This helps people react fast to changes in the room.

Picking the right dehumidification system can save energy and lower costs.

Image Source: unsplash

A dry room controlled environment is a special kind of room. It keeps the air very dry, with humidity below 1%. This dryness protects sensitive products from water damage. Many industries use dry rooms to stop moisture from causing issues.

Dry rooms use strong dehumidification systems to keep air dry.

Airlocks at doors help keep outside humidity out.

Special HVAC systems work to keep conditions steady.

Builders seal the room tightly so no outside air gets in.

Dry rooms are used where even a little moisture can ruin things. The pharmaceutical industry uses dry rooms for lyophilization, which means freeze-drying. Labs that make vaccines and drugs also use dry rooms. These rooms help keep medicines safe and stable. They also make drying faster and better, which helps product quality.

Amber makes dry rooms that follow strict rules. You get complete solutions, including design, building, and support after you buy. Amber’s team uses strong materials and new technology to build safe spaces for your needs.

You may wonder how dry rooms are different from other spaces like cleanrooms. The main difference is how they control humidity. Dry rooms keep humidity very low to protect products from moisture. Cleanrooms focus on keeping dust and particles out. They do not always control humidity as much as dry rooms.

Dry rooms are needed for products that can be ruined by moisture.

Cleanrooms keep out dust and particles but may not keep air as dry.

Sometimes, a dry room is called a dry clean room because it controls both particles and humidity.

You need a dry room controlled environment if you work with electronics, semiconductors, or medicines. In these areas, moisture can cause big problems. For example, too much humidity can make electronics stop working. In medicines, moisture can make drugs weaker. Aerospace companies use dry rooms to stop rust in important systems.

When you pick Amber, you get a partner who knows how to build both dry rooms and cleanrooms. Amber understands dry room controlled environments and can make them fit your industry.

You need strong dehumidification systems to keep your dry room safe. These systems take water out of the air. They help you reach very low humidity. There are different types you can pick. Each type works in its own way.

Solid desiccant systems use special stuff to soak up water. You can use them in big dry rooms. They work well even when it is cold.

Liquid desiccant systems use liquids to grab water from the air. These systems can make air very dry. They save energy by using heat again. You need to check and fix them often.

Cryogenic dehumidification systems make air very cold. This makes water turn into drops and leave the air. These systems use lots of energy. They help you keep the room super dry.

Membrane dehumidification systems use filters to split water from air. These systems are small and save energy. They can be hard to take care of in big rooms.

The average energy use for dehumidification systems in dry rooms is about 4.40×10^6 kJ per person each year. This shows why it is important to pick the best system for your needs.

Amber gives you modular dehumidification solutions for your space. You get good performance and easy upgrades when you need them.

Airlocks help keep your dry room safe from outside air. When you go in or out, airlocks keep humidity low. The table below shows how airlocks work:

Feature | Description |

|---|---|

Airlocks Control Environmental Conditions | Airlocks keep temperature, humidity, and pressure steady in dry rooms. |

Kardex Dry Room Storage | Keeps humidity below 1%, protecting sensitive materials from moisture. |

Airlocks reduce air exchange, helping you keep humidity and temperature steady. |

Amber’s entry solutions use smart locks and controls. You get easy movement and strong protection from outside air.

You need special HVAC systems to keep your dry room at the right temperature and humidity. These systems move air and use strong filters to clean it. The table below shows important features:

HVAC Feature | Description |

|---|---|

Temperature Control | Keeps your dry room at the right temperature. |

Humidity Control | Uses dehumidification to keep humidity very low. |

Airflow Management | Moves air evenly through your dry room. |

Good filtration is important too. HEPA filters catch almost all particles that are 0.3 microns or bigger. ULPA filters catch even smaller particles, up to 99.9995% of those 0.12 microns or larger. These filters help keep your air clean. This is important for electronics, medicine, and labs.

Amber uses strong materials like stainless steel and SUS304 in its HVAC and filtration systems. You get safe, clean air for your dry room.

When you build a dry room, you must pick the right materials. These materials keep water out and protect your products. The walls, floors, and ceilings need to seal tightly. This stops outside air from coming in. Stainless steel and SUS304 are good choices. They do not rust and last a long time. Sandwich panels have special insulation inside. These panels help keep the room cool and block water in the air.

Amber uses strong materials for every dry room. You get doors that seal tight and windows with two layers of glass. These things help keep the room dry. Joints and corners use special glue to fill gaps. This glue stops leaks. You should check these places often to make sure the seals work well.

Here is a table that shows common sealed construction materials and what they do:

Material | Benefit |

|---|---|

Stainless Steel | Does not rust, strong, easy to clean |

SUS304 | Lasts long, does not corrode easily |

Sandwich Panels | Insulates well, blocks water |

Double Glazed Glass | Keeps water out, seals tight |

Special Sealants | Fills spaces, stops leaks |

Using sealed construction materials makes building and running a dry room easier. You keep your products safe and your room protected.

You need smart systems to watch your dry room. These systems check humidity, temperature, and air quality all the time. You see live data on screens. This helps you act fast if something changes. Sensors notice small changes in the room. If the humidity goes up, the system fixes it right away.

Modern systems use automation. You set the limits for humidity and temperature. The system keeps everything steady by itself. You save energy because it only works when needed. The system records all changes, so you meet industry rules. This helps you pass checks and keep products safe.

Tip: You can link your system to the cloud. This lets you check your dry room from anywhere. You get alerts if there is a problem.

Here are some ways smart monitoring and controls help you:

You get live data to make quick choices.

You control humidity very well.

Automation keeps the room at the best level.

You use less energy and save money.

You follow strict industry rules.

You make your products better and work faster.

You use sensitive sensors for better results.

You can check your dry room from far away with IoT and cloud.

Amber gives you systems that fit your needs. You get easy dashboards and sensors you can trust. These tools help you keep your dry room safe and working well.

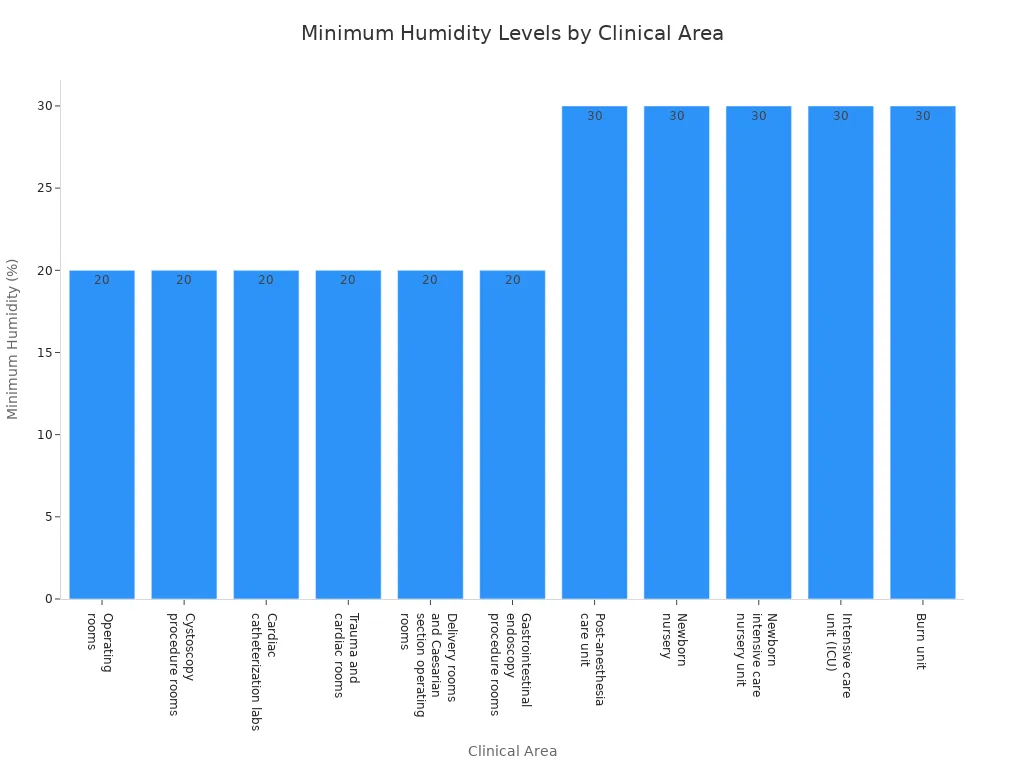

You must keep humidity low in a low-humidity room. This helps protect products from water damage. The dry room industry standard sets humidity below 1% for sensitive work. Medical rooms have different minimum humidity levels. Operating rooms need at least 20% humidity. Nurseries and ICUs need at least 30%. Here is a table that shows these rules:

Clinical Area | Minimum Humidity Level |

|---|---|

Operating rooms | 20% |

Cystoscopy procedure rooms | 20% |

Cardiac catheterization labs | 20% |

Trauma and cardiac rooms | 20% |

Delivery rooms and Caesarian section operating rooms | 20% |

Gastrointestinal endoscopy procedure rooms | 20% |

Post-anesthesia care unit | 30% |

Newborn nursery | 30% |

Newborn intensive care nursery unit | 30% |

Intensive care unit (ICU) | 30% |

Burn unit | 30% |

You can use tools to control humidity. Dehumidifiers take water out of the air. Air movers help dry things faster. Controlled heating makes water leave surfaces quickly. Moisture monitors, like hygrometers, show humidity levels right away. These steps are important for low-humidity rooms.

Tip: Check your humidity control systems often. Regular checks help you find problems early and keep your room safe.

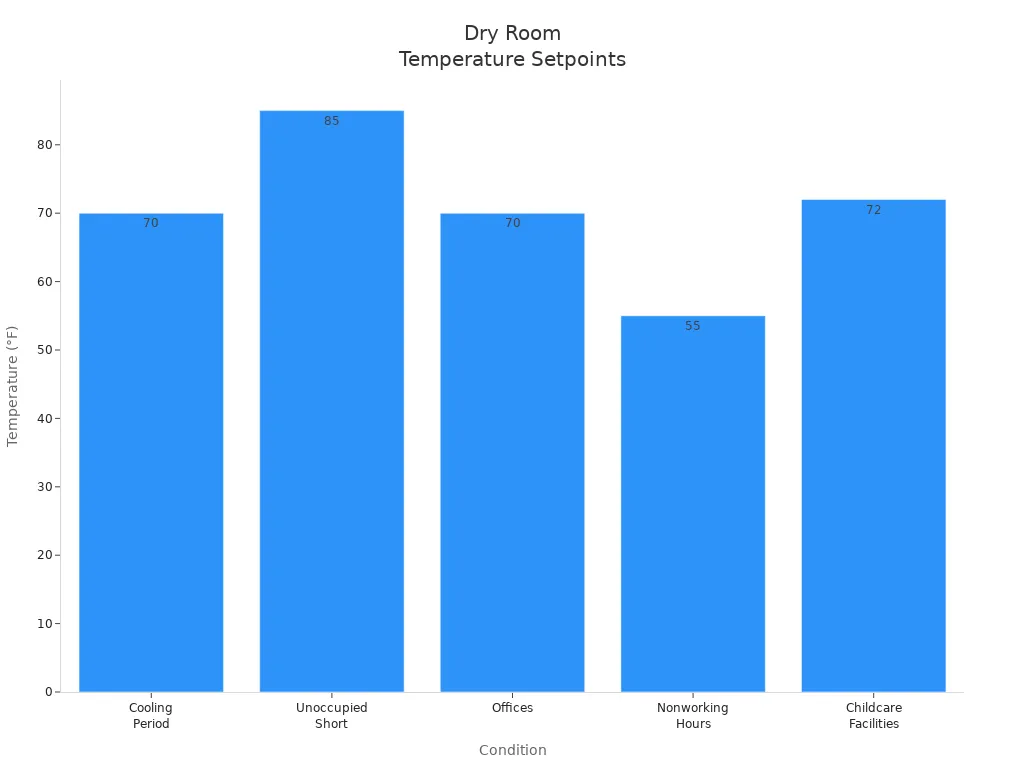

Temperature control matters as much as humidity control. You need to keep the temperature steady to protect items. Dry room standards suggest different temperature ranges for each use. Cooling periods stay at 70°F (21°C) with humidity under 60%. Offices should be at 70°F (21°C). Server rooms work best between 68°F and 71°F. This stops equipment from getting too hot.

Condition | Temperature Range (°F) | Relative Humidity (%) |

|---|---|---|

Cooling Period | 70°F (21°C) | < 60% |

Unoccupied Short | 85°F (29°C) | < 70% |

Heating Period | N/A | 30% - 50% |

Offices | 70°F (21°C) | N/A |

Nonworking Hours | 55°F (12.8°C) | N/A |

Childcare Facilities | 72°F (22.2°C) | N/A |

Use sensors to watch the temperature closely. If the temperature changes too much, products may not stay safe. Keeping the right temperature also helps control humidity better.

Air quality management keeps your room clean and safe. You need to check ductwork and vents for leaks. Looking at them helps you find problems early. If you checked the system last year, you may not need a new check now. Some ductwork is hard to reach, so you may not need to check it every time.

Compliance Requirement | Description |

|---|---|

Visual Inspection of Ductwork | Inspect the vent collection system ductwork and dry particulate control unit for leaks and structural integrity. |

Initial Inspection Exemption | An initial inspection is not required if a record of inspection exists within the past 12 months. |

Ductwork Inspection Exemption | Initial inspection of unsafe or difficult ductwork is not required. |

Certification Requirement | If PM concentration is certified below a threshold, specific management practices apply. |

Initial Visual Inspection | Conduct an initial visual inspection of the vent collection system ductwork for leaks. |

Use HEPA filters and keep air systems clean. This helps you follow air quality rules and keeps products safe. Good air quality, steady temperature, and strong humidity control all help your low-humidity room work well.

You need good rules and checks to keep your low-humidity room safe. These rules help you follow industry standards and protect your products. You must check your room often and write down important data. This helps you find problems early and fix them fast.

Routine checks are the first step. You count particles in the air. You watch pressure changes. You write down temperature and humidity. You look at this data for patterns. If something looks wrong, you act quickly. This keeps your low-humidity room working well.

Requalification is another important rule. You must test your low-humidity room at certain times. For ISO Class 5 rooms, you test every six months. For ISO Class 6 to 8 rooms, you test every year. If you change your building or process, you test sooner. This makes sure your room still meets strict rules.

ISO 14644-2 gives you clear steps for checking your room. You need a plan that shows where you will test air. You must say how often you will check. You set levels that will cause alerts. You use a risk-based plan. This means you focus on the most important areas for your products.

Here is a table that shows the main rules and checks for a low-humidity room:

Protocol/Standard | Description |

|---|---|

Routine Monitoring | You count particles, watch pressure, and write down temperature and humidity. You look at data and act if results go above safe levels. |

Requalification | You test your low-humidity room at set times or after changes to make sure it meets rules. |

ISO 14644-2 | You follow steps for checking plans, testing spots, how often to check, alert levels, and what to do next. |

Tip: You should keep good records of all checks and actions. Good records help you show you follow rules during audits and inspections.

You can use smart sensors and automatic systems to make checking easier. These tools give you live data and alerts. You can see problems as soon as they happen. This helps you keep your low-humidity room safe and steady.

You must teach your staff to follow all rules. Everyone should know how to use checking tools and what to do if something goes wrong. Regular training keeps your team ready and your low-humidity room in good shape.

You need to look at your rules often. Change your checks when standards change or when you add new equipment. This keeps your low-humidity room up to date and ready for anything.

A strong system for rules and checks protects your products and helps you follow industry standards. You keep your low-humidity room safe, working well, and ready for inspection.

Many industries use electronics and semiconductors. These products need dry rooms to stay safe. Even a little water in the air can break electronics. Dry rooms lower the chance of damage. They help your products work well.

You must keep humidity and air clean in these rooms. Semiconductor cleanrooms need humidity between 30% and 50%. This stops bacteria from growing. It also keeps workers comfortable. You need vertical laminar airflow too. HEPA filters clean the air. They keep temperature and humidity steady.

Cleanrooms for electronics must follow strict ISO rules. ISO 14644-1 Class 5 lets only 3,520 tiny particles per cubic meter. You must use ISO 14644-2 for quality checks. These rules help you make safe products.

Tip: Dry rooms protect electronics from rust and water damage. This helps you avoid repairs and keeps your business running.

Battery making needs dry rooms. Water can ruin batteries and make them unsafe. In lithium-ion battery factories, low humidity stops electrolyte problems. It keeps conductivity high. If water gets in, it can rust electrode materials. This makes batteries work badly and can be dangerous.

Dry rooms stop short circuits and thermal runaway. These problems can cause fires or explosions. Keeping humidity low makes batteries last longer and work better.

Here is a table that shows why industries use dry rooms:

Industry | Reason for Dry Room Use |

|---|---|

Battery Production | Stops water damage and makes batteries safer. |

Pharmaceuticals | Keeps drugs safe from water and stable. |

Electronics | Lowers risk of damage from water. |

Medical Applications | Keeps things sterile and stops water problems. |

You get better batteries with dry room controlled environments. These rooms help you meet rules and keep products safe.

Pharmaceutical and medical device factories need dry rooms. Humidity control keeps drugs and devices stable. If water gets in, it can cause chemical problems. This makes products weaker and unsafe.

Dry rooms stop rust and germs from growing. They help medical devices work right. They also keep drugs strong and lasting longer.

Here are ways dry rooms help in this field:

You keep drugs and devices working well.

You stop chemical problems and reactions from water.

You make products last longer and follow rules.

Note: Dry rooms help you follow safety and quality rules. You protect patients and keep your business trusted.

Controlled environments help your products meet high standards. This builds trust with customers and regulators.

You need to control humidity in food processing to keep products safe and fresh. Dry room controlled environments help you manage moisture in the air. When you keep humidity low, you stop bacteria and mold from growing. This protects food from spoilage and keeps it safe for people to eat.

High humidity can slow down drying. You may use more energy and spend more money if the air is too wet. Dry rooms use dehumidifiers to pull water out of the air. You can set the humidity level for each type of food. For example, dried fruits need very low humidity to stay crisp. Cheese and cured meats need special humidity levels to keep their texture and taste.

Tip: You can use sensors to check humidity all the time. If the level goes up, you fix it fast. This helps you avoid problems before they start.

Food processing plants use dry rooms for many reasons:

You keep food quality high.

You lower the risk of contamination.

You save energy and reduce costs.

You meet safety rules and standards.

Here is a table that shows how dry rooms help different foods:

Food Type | Benefit of Dry Room Environment |

|---|---|

Dried Fruits | Stays crisp, does not spoil |

Cheese | Keeps texture, stops mold |

Cured Meats | Maintains flavor, prevents bacteria |

Spices | Stays dry, keeps taste strong |

Powdered Foods | No clumping, stays fresh |

You can see that each food needs a special environment. Dry rooms let you set the right conditions for each product. You use less energy because drying happens faster. You also keep your products safe from germs and mold.

Amber gives you turnkey dry room solutions for food processing. You get strong dehumidifiers, smart sensors, and sealed construction. You can trust Amber to help you meet food safety standards. The company uses high-quality materials like stainless steel and SUS304. These materials do not rust and are easy to clean. You get a safe space for your food products.

Note: When you use Amber’s dry room solutions, you protect your brand and keep your customers happy. You make sure every batch meets quality and safety rules.

Food processing needs dry room controlled environments to work well. You keep food fresh, safe, and ready for the market.

You might wonder how dry rooms and cleanrooms work. Both protect sensitive products, but they do it differently. Dry rooms keep humidity very low. This stops water from hurting things like batteries or medicines. Cleanrooms keep dust and tiny particles out. They use special filters and airflow to clean the air.

Here is a table that shows how their controls are different:

Feature | Dry Room Controlled Environment | Cleanroom |

|---|---|---|

Definition | Area with set conditions | Controlled space with strict rules |

Particle Contamination | No set rules for particles | Must follow rules for particle levels |

Applications | Used in labs and engineering | Used in making chips and medicines |

Energy and Technology Needs | Uses less energy and tech | Needs more energy and advanced systems |

Dry rooms do not always have strict dust rules. Cleanrooms must follow rules for particles. Cleanrooms use more energy because they need better systems to clean air.

You use dry rooms when you need to control moisture. These rooms are good for making batteries, drying food, and some labs. Dust is not a big worry in these places. Cleanrooms are needed when you must keep out dust and germs. You find cleanrooms in hospitals, chip factories, and medicine plants.

Dry rooms follow rules for humidity. Some rules say humidity must stay below 1%. Cleanrooms follow ISO rules for clean air. ISO 14644-1 sets limits for particles in the air. You must test cleanrooms often to make sure they meet these rules.

Dry rooms can have problems if doors open too much. Humidity can go up. If the room is not sealed well, equipment may not work right. You need to check your systems often to stop these problems.

Dry rooms and cleanrooms share some things. Both have sealed walls and special doors. Both use strong HVAC systems. You find HEPA filters in both rooms. These filters help keep air clean. Both use monitors to check temperature and humidity.

Some places need both dry air and clean air. You may build a dry cleanroom for this. It gives you both benefits. Your products stay safe from water and dust.

Both rooms can have problems. Sensors might break. Filters can get clogged. You need to check and fix things often to keep the room safe.

Tip: Train your team to notice changes in air or humidity. Acting fast helps you stop bigger problems later.

Today, you can use automation and smart monitoring in your dry room. These new systems help you watch and control your room all the time. Some of the newest technologies in 2025 include:

AI looks at data from IoT sensors. It helps your system work better every second.

Systems change when the weather or equipment changes. This gives you good results all the time.

Smart controls help you save energy. They also keep your dry room working well.

You can use special tools to check your room’s conditions. The DMP1 Dew Point and Temperature Probe gives quick and accurate readings. It is great for making lithium-ion batteries. You can connect it to your main monitoring system easily.

Feature | Description |

|---|---|

Product | DMP1 Dew Point and Temperature Probe |

Measurement | Dew point down to -70°C |

Response Time | Much faster than other probes |

Application | Good for battery production |

Integration | Works with main monitoring system |

Maintenance | Needs little care and lasts a long time |

You can use AI-driven Building Management Systems too. These systems connect with HVAC, lighting, and security. They use machine learning to change airflow and guess when you need repairs. This keeps your dry room safe and working well.

You can save money and help the planet with new energy-saving technology. Many dry rooms now use energy-efficient dehumidifiers and smart systems. These upgrades help you use less power and keep humidity right.

Aspect | Impact |

|---|---|

Operational Costs | Lower because of energy-saving dehumidifiers |

Performance | Better with advanced and IoT-enabled systems |

Sustainability | Improved by using energy-efficient solutions |

Energy Use | Less energy needed with better humidity control |

Example | Munters’ dehumidifiers use new rotor technology to save energy |

Cost Savings | Big savings reported by the U.S. Department of Energy |

If you use customized minienvironments, you need less air for drying. This means your system uses less energy to keep the right conditions. You save money and help the environment too.

Amber gives you the newest dry room technology. You get ready-to-use solutions with smart automation, strong sensors, and energy-saving systems. Amber’s dry rooms use high-quality materials like stainless steel and SUS304. This keeps your space safe and clean. Amber’s modular designs fit your needs and can grow with your business.

Amber’s smart monitoring tools let you see your room’s status from anywhere. You get alerts if something changes, so you can act fast. With Amber, you follow strict industry rules and keep your products safe. You also save energy and lower costs with every project.

Tip: Pick Amber’s advanced dry room solutions to protect your products, save energy, and stay ahead in your field.

You need a dry room controlled environment to keep products safe from water. Low humidity stops water from hurting your products. This helps you make better things and keeps people safe. In high-tech jobs, even a little water can ruin electronics, batteries, or medicines. Dry rooms help you in many ways:

You stop moisture from getting in. This keeps products clean and strong.

You help workers do their jobs faster. Stable air means fewer mistakes.

You save money because you have fewer repairs. You do not need to recall products as much.

You make things safer. Less water in the air lowers the chance of fire or explosion.

Dry rooms help you avoid big problems. Water can make electronic parts rusty. It can break insulation and make things weak. Sometimes, surfaces do not stick together right because of water. If water gets in, it can contaminate your products. Dry rooms stop these problems before they happen.

You also follow strict rules when you use dry rooms. Low humidity keeps your work steady. You get more good products and better results. Your products work well, and people trust your brand.

Tip: Check your dry room often and use smart sensors. You find problems early and fix them quickly.

Dry room controlled environments help your business get bigger. Many companies need dry rooms to make new things and improve old ones. You see dry rooms in battery factories, electronics plants, and medicine labs. These rooms let you use new materials and try new ways to make things.

Here is a table that shows how dry rooms help different industries:

Industry | Benefit of Dry Room Environment |

|---|---|

Battery Production | Safer batteries, longer life |

Electronics | Reliable devices, fewer defects |

Pharmaceuticals | Stable drugs, better shelf life |

Food Processing | Fresher products, less spoilage |

You can use dry rooms to test new ideas. When you control humidity, you can work with sensitive stuff. You can make products that last longer and work better. Dry rooms help you meet world rules, so you can sell your products in more places.

Innovation happens faster in dry rooms. You can change your process and see results quickly. You use smart tools to watch every step. This helps you find new ways to save energy and spend less money.

Dry room controlled environments give you what you need to lead your field. You protect your products, grow your company, and stay ahead of others.

You need a dry room controlled environment to keep sensitive products safe from water. These rooms help you ensure that your products remain in good condition. They also help keep your work environment safe. In 2025, low-humidity rooms will be very important for new technology. They assist you in adhering to strict regulations. Amber gives you ready-to-use solutions and expert help.

️ Pick Amber to build a safe and clean space for your business. Check out Amber’s options to find what you need for your controlled environment.

You use a dry room to keep humidity very low. This protects sensitive products from water damage. Dry rooms help you make safe batteries, electronics, medicines, and food.

A dry room controls humidity. A cleanroom controls dust and particles. Some spaces need both. You choose the right room based on what you need to protect.

You find dry rooms in battery factories, electronics plants, pharmaceutical labs, and food processing. These industries need low humidity to keep products safe and high quality.

You use sensors and smart systems to check humidity all the time. These tools alert you if levels change. You can see live data on screens or your phone.

You should use stainless steel, SUS304, sandwich panels, and double-glazed glass. These materials seal tightly and resist rust. They help keep your room dry and safe.

Yes! You can choose the size, layout, and features. Amber offers modular designs. You get a dry room that fits your process and space.

You should check sensors, filters, and seals often. Most experts suggest monthly checks. Regular maintenance helps you catch problems early and keep your room working well.